Welcome Our Company!

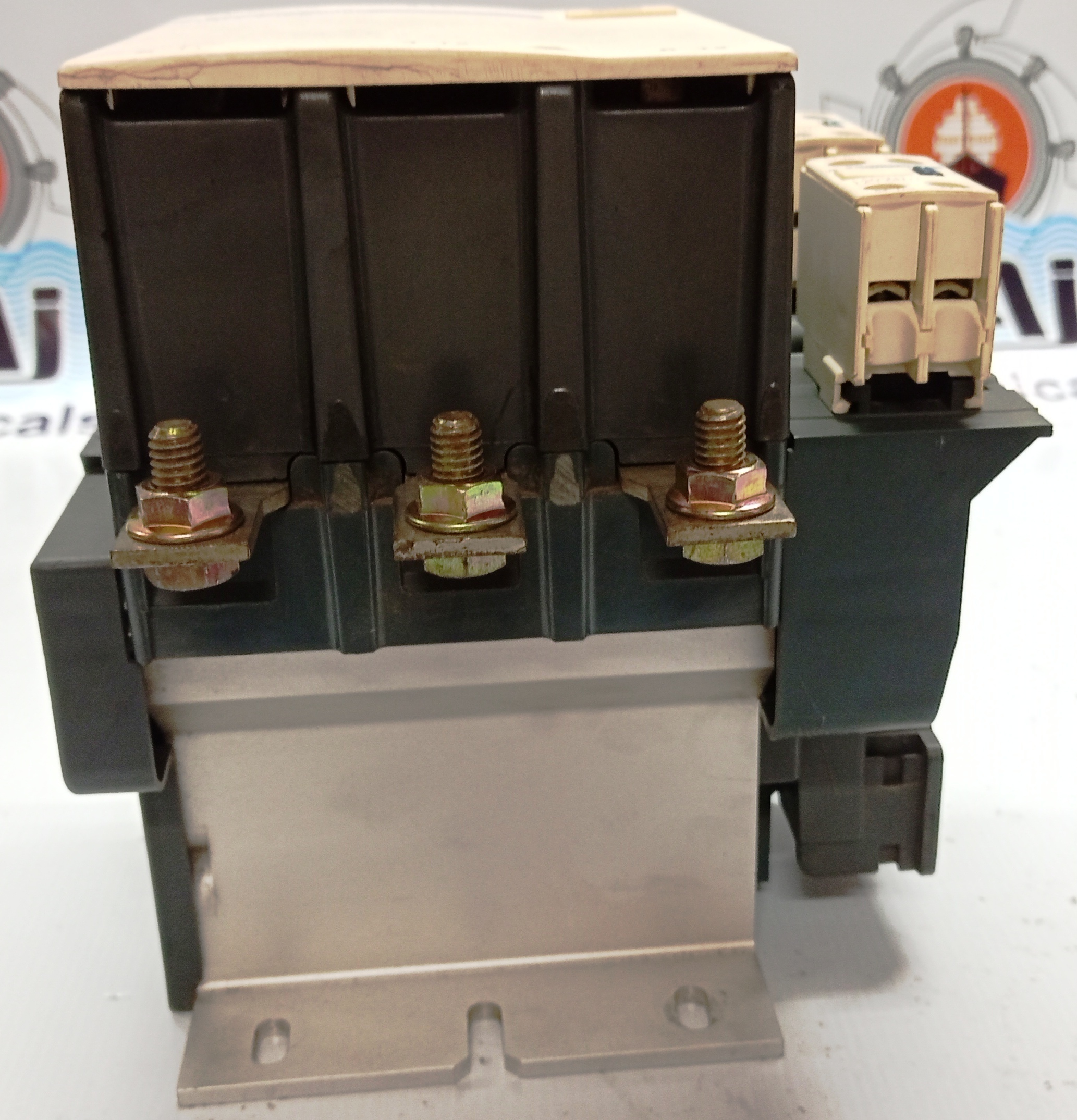

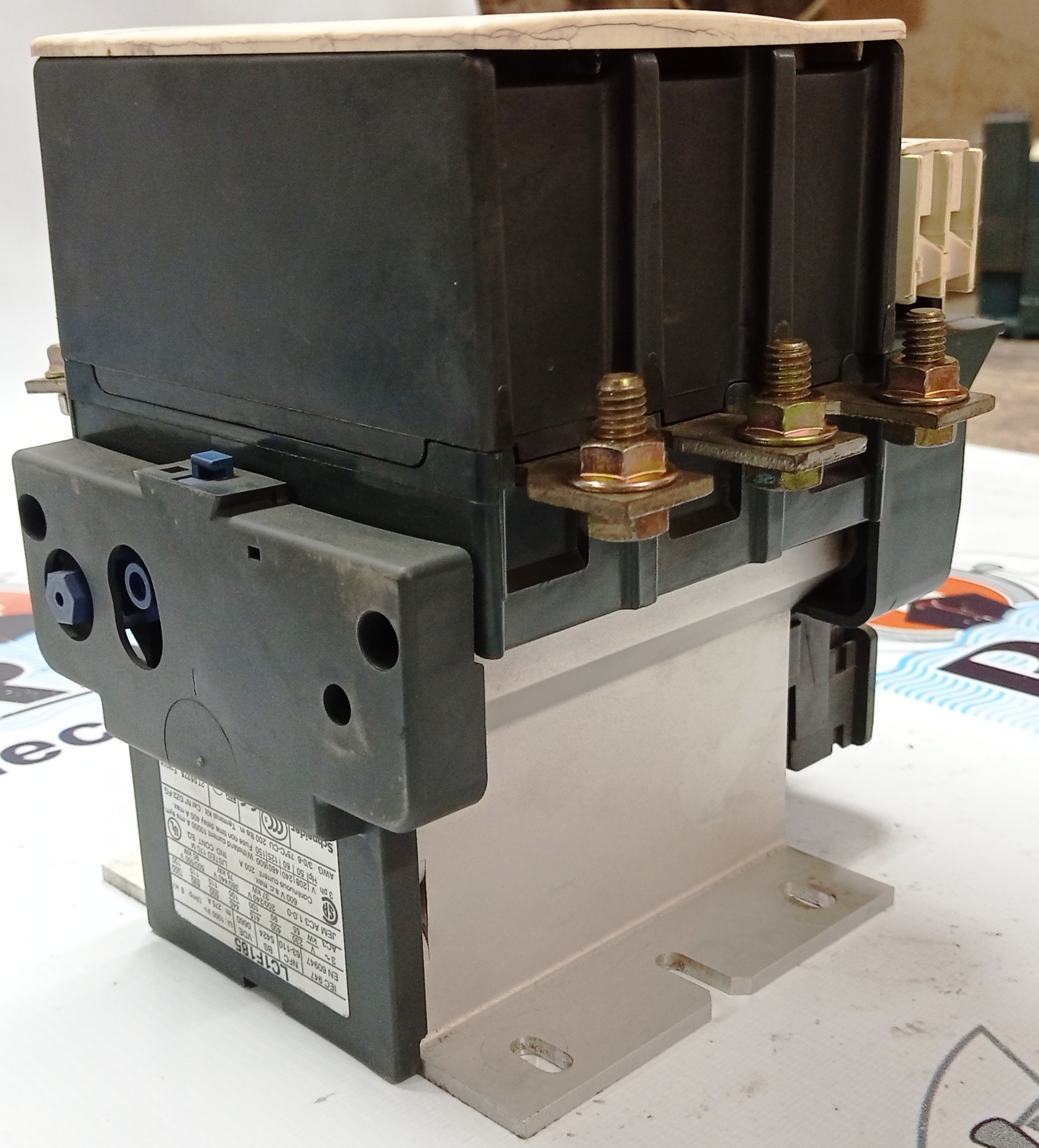

TELEMECANIQUE LC1F185 CONTACTOR

TELEMECANIQUE LC1F185 CONTACTOR Specification

- Humidity %

- ≤ 95% RH (non-condensing)

- IP Rating

- IP20

- Connector Type

- Screw Type

- Surface Finish

- Matte

- Operating Temperature

- -5°C to +60°C

- Shape

- Rectangular

- Power Factor

- 0.8 (approx)

- Feature

- High Current Capacity, Robust Design

- Efficiency

- High Efficiency

- Mounting Type

- Panel/DIN Rail Mounting

- Insulation Material

- Thermoplastic

- Overheating Protection

- Provided

- Product Type

- AC Power Contactor

- Application

- Industrial Motor Control, Power Switching

- Protection Level

- IEC 60947-4-1

- Frequency (MHz)

- 50/60 Hz

- Rated Voltage

- 690V AC

- Energy Consumption

- 90 VA (Pick-up), 9 VA (Hold)

- Output Type

- NO/NC Contacts

- Color

- Black & Blue

- Dimension (L*W*H)

- 185mm x 133mm x 160mm

- Weight

- 7.5 kg

- Phase

- Three Phase

- Size

- Standard Industrial

- Input Voltage

- 220V / 380V / 415V AC Coil Voltage

- No Of Poles

- 3 Poles

- Connection Type

- Screw Terminal

- Material

- High-grade Flame Retardant Plastic & Metal

- Coil Consumption

- 90 VA (Pick-up), 9 VA (Hold)

- Rated Current

- 185A

- Vibration Resistance

- 5g, 10-150 Hz

- Contact Material

- Silver Alloy

- Mechanical Endurance

- 10 million operations

- Electrical Endurance

- 1 million operations at rated load

- Shock Resistance

- 15g, 11 ms

- Auxiliary Contacts

- 2 NO + 2 NC

TELEMECANIQUE LC1F185 CONTACTOR Trade Information

- Payment Terms

- Cash in Advance (CID)

- Sample Available

- Yes

- Main Domestic Market

- All India

About TELEMECANIQUE LC1F185 CONTACTOR

A contactor is an electrical device which is used for switching an electrical circuit on or off. ... These contacts are in most cases normally open and provide operating power to the load when the contactor coil is energized. Contactors are most commonly used for controlling electric motors.Superior Endurance and Longevity

With a mechanical endurance of 10 million operations and an electrical lifespan of 1 million operations at rated load, the LC1F185 contactor is built for sustained, intensive use. Its shock resistance (15g) and vibration resilience make it suitable for challenging industrial environments, ensuring continuous and reliable performance.

Versatile Industrial Application

This contactor is designed to handle high-current applications, making it ideal for motor control and power switching in factory automation, heavy machinery, and process industries. Its three-pole configuration, flame-retardant housing, and compliance with IEC 60947-4-1 offer enhanced safety and flexibility for various installation requirements.

Efficient and User-Friendly Design

Featuring energy-efficient coil consumption (90 VA pick-up, 9 VA hold) and screw-type terminals for secure connection, the LC1F185 combines operational efficiency with ease of installation. The matte surface finish and black-blue color scheme complement modern industrial setups, while the panel/DIN rail mounting option simplifies integration.

FAQ's of TELEMECANIQUE LC1F185 CONTACTOR:

Q: How can the TELEMECANIQUE LC1F185 contactor be mounted in an industrial control panel?

A: The LC1F185 contactor supports both panel and DIN rail mounting types, enabling flexible and secure installation within standard industrial enclosures. Its screw terminal connections further facilitate easy and reliable wiring.Q: What are the main benefits of using this contactor for industrial motor control applications?

A: Designed for high-current capacity, this contactor offers robust mechanical endurance, silver alloy contacts for superior conductivity, effective overheating protection, and high efficiency. These features contribute to reliable operation and prolonged service life in demanding industrial environments.Q: When should the contactor's electrical and mechanical endurance be considered for replacement planning?

A: It's recommended to monitor the total number of operations-mechanical endurance is 10 million and electrical is 1 million at rated load. Replacement or maintenance planning should align with these lifecycle milestones to avoid unscheduled downtime.Q: Where is the LC1F185 contactor typically used?

A: This contactor is widely used across industrial motor control panels, factory power distribution boards, and process automation setups in sectors such as manufacturing, utilities, and mining, primarily for switching and protecting three-phase loads.Q: What auxiliary contacts are provided, and how can they be utilized?

A: The LC1F185 provides 2 Normally Open (NO) and 2 Normally Closed (NC) auxiliary contacts. These can be used for signaling, interlocking, or controlling supplementary circuits alongside the main switching function.Q: How does the contactor ensure safety and durability in adverse conditions?

A: Safety is enhanced through IP20 protection, high-grade flame-retardant insulation, shock resistance up to 15g, vibration resistance, and efficient overheating protection. It can reliably operate within the temperature range of -5C to +60C and up to 95% relative humidity (non-condensing).

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in TC Contactor Category

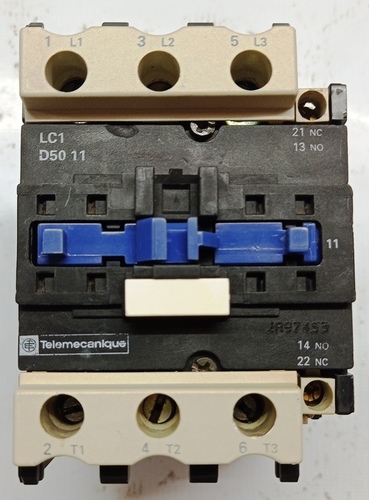

TELEMECANIQUE LC1D5011 CONTACTOR

Input Voltage : 230 V AC Coil

Size : Standard IEC

Surface Finish : Matte

Color : Grey & Blue

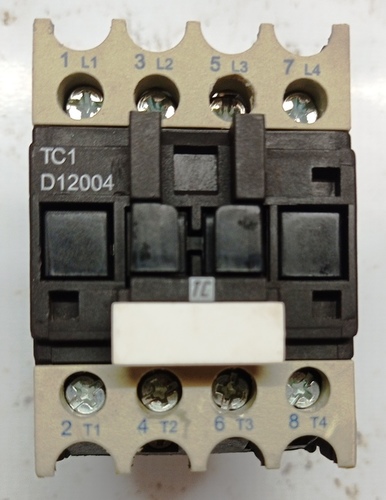

TELEMECANIQUE TC1D12004 CONTACTOR

Input Voltage : 220240 V AC coil

Size : Standard (TC1D12 series)

Surface Finish : Matte

Color : Grey/Blue

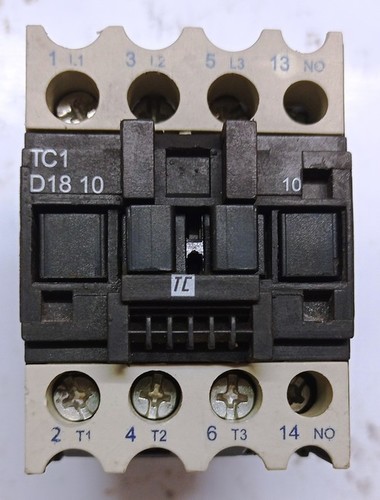

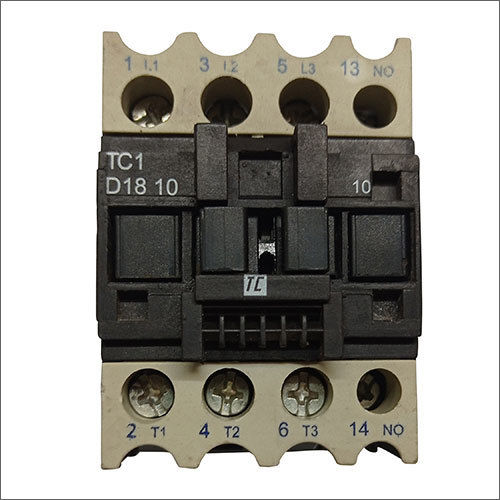

TELEMECANIQUE TC1D 1810 CONTACTOR

Input Voltage : 220V AC

Size : 18A

Surface Finish : Matte

Color : Grey & Blue

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese