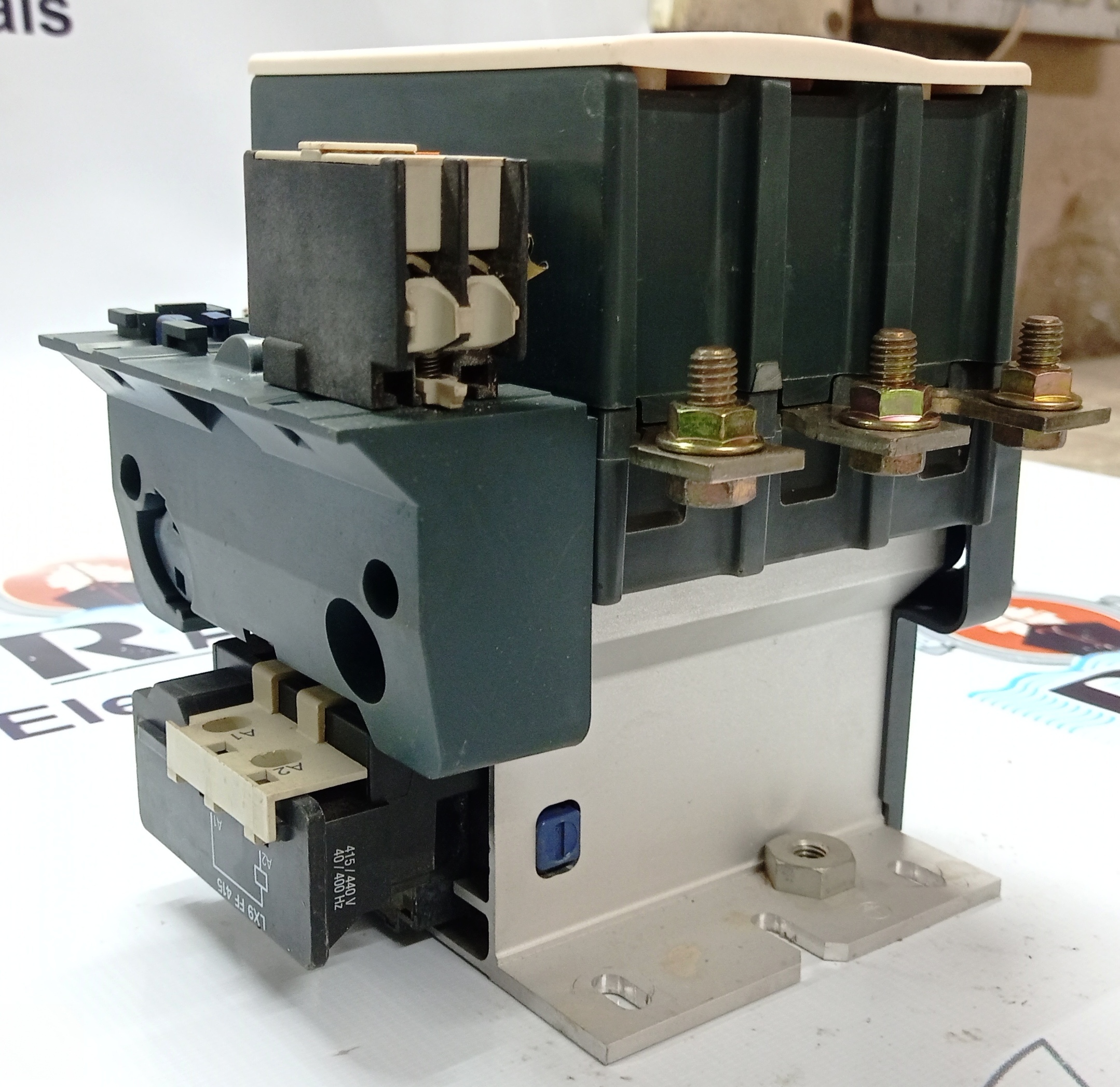

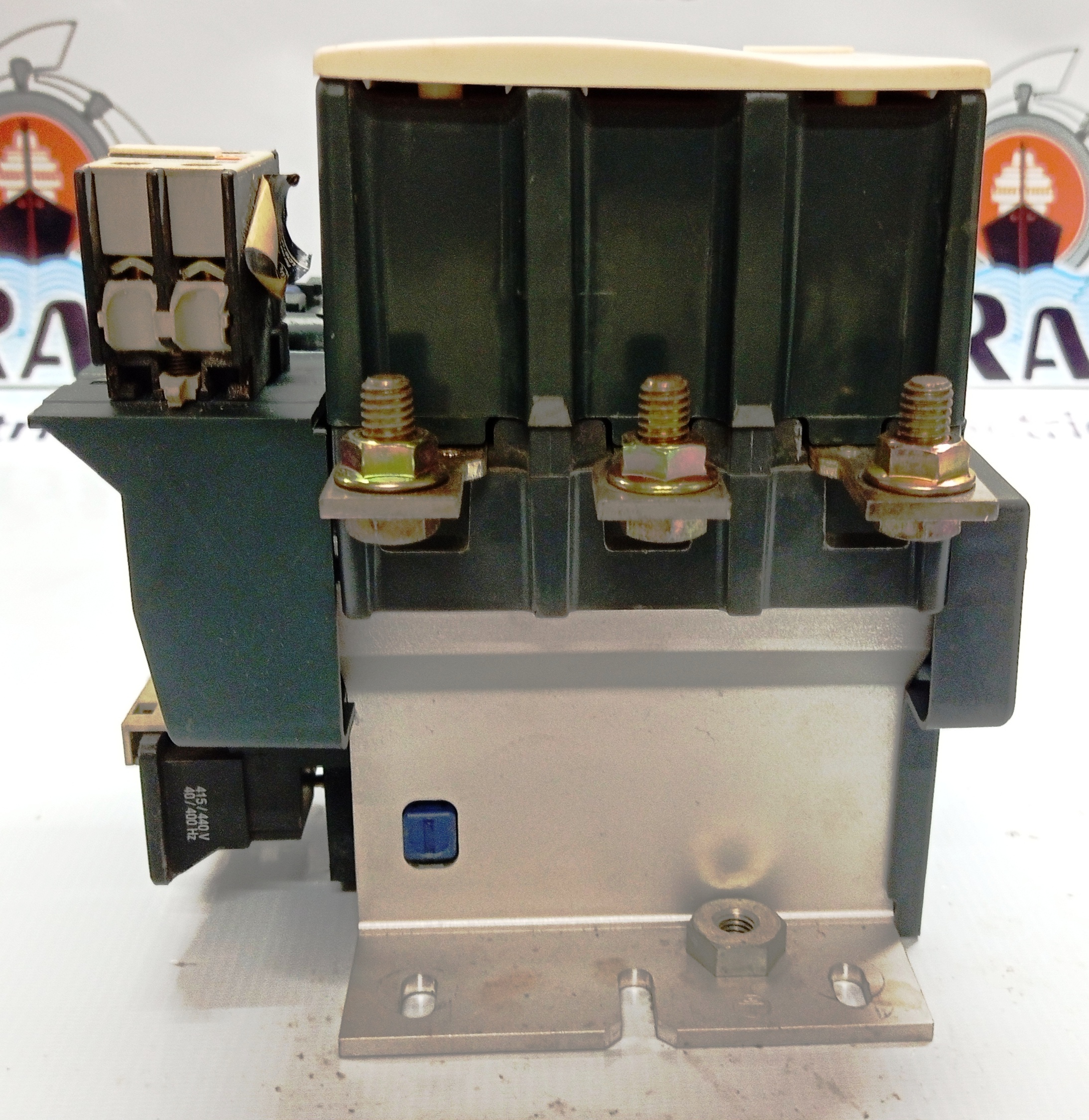

TELEMECANIQUE LC1F150 CONTACTOR

TELEMECANIQUE LC1F150 CONTACTOR Specification

- Overheating Protection

- Yes (with thermal overload relay accessory)

- Humidity %

- Up to 95% RH (non-condensing)

- Surface Finish

- Matte

- Power Factor

- 0.8

- Efficiency

- High

- Feature

- High Durability, Heavy Duty Contacts, Low Power Consumption

- Connector Type

- Screw Clamp Type

- IP Rating

- IP20

- Operating Temperature

- -5°C to +60°C

- Shape

- Rectangular

- Mounting Type

- DIN Rail / Panel Mount

- Insulation Material

- Thermoplastic/Epoxy Moulded

- Product Type

- Power Contactor

- Application

- Motor Control, Power Switching, Industrial Automation

- Protection Level

- IP20

- Frequency (MHz)

- 50/60 Hz

- Rated Voltage

- 690 V AC

- Energy Consumption

- 12 VA (Holding)

- Output Type

- NO+NC

- Color

- Grey & Blue

- Dimension (L*W*H)

- 180 x 142 x 142 mm

- Weight

- 4.7 kg

- Phase

- Three Phase

- Input Voltage

- 230V AC (Coil Voltage)

- Size

- 150 A Frame Size

- No Of Poles

- 3

- Connection Type

- Screw Terminal

- Material

- Flame Retardant Plastic & Metal

TELEMECANIQUE LC1F150 CONTACTOR Trade Information

- Payment Terms

- Cash in Advance (CID)

- Sample Available

- Yes

- Main Domestic Market

- All India

About TELEMECANIQUE LC1F150 CONTACTOR

A contactor is an electrical device which is used for switching an electrical circuit on or off. ... These contacts are in most cases normally open and provide operating power to the load when the contactor coil is energized. Contactors are most commonly used for controlling electric motors.Engineered for Demanding Industrial Environments

The LC1F150 contactor is designed with industrial automation and motor control in mind, supporting three-phase applications and handling up to 150A. Its flame-retardant, matte-finished enclosure, along with comprehensive protection features, guarantees safe and uninterrupted operations. Certified by IEC, CE, cULus, and EAC, it meets global standards, delivering reliability and efficiency even in harsh environments.

Flexible Installation and Connection Options

This model offers versatile installation, supporting both DIN rail and panel mounting. The screw clamp terminal design facilitates secure connections for cables ranging from 35 to 70 mm2. With an ambient storage capacity from -40C to +85C and operating temperatures between -5C to +60C, the LC1F150 adapts easily to diverse industrial settings.

Exceptional Durability and Operational Life

Built to last, the LC1F150 features a mechanical life span of 10 million cycles and an electrical endurance of 1 million operations. The heavy-duty contacts and high-efficiency design contribute to reliable long-term performance and minimal maintenance, making it a valuable asset for continuous industrial operations.

FAQ's of TELEMECANIQUE LC1F150 CONTACTOR:

Q: How is short circuit protection implemented in the TELEMECANIQUE LC1F150 contactor?

A: The LC1F150 incorporates short circuit protection using a backup fuse. This mechanism helps safeguard the contactor and connected equipment from potential damage due to fault currents.Q: What types of mounting options are available for the LC1F150 contactor?

A: You can install the LC1F150 contactor using either a DIN rail or direct panel mounting, allowing flexibility to suit various control panel setups.Q: When should I add auxiliary contacts to the LC1F150, and what configurations are supported?

A: Auxiliary contacts are used when you require extended control or signaling functions. The contactor comes with 2NO + 2NC auxiliary contacts, and you can add more if your application demands increased functionality.Q: What steps are involved in connecting cables to this contactor?

A: Connect the cables using the screw clamp terminals which support wires between 35-70 mm2. Ensure all terminals are securely tightened according to the manufacturer's torque specifications to ensure reliable connectivity and performance.Q: Where is the LC1F150 contactor typically used?

A: This contactor is widely deployed in industrial automation, motor control, power switching, and similar heavy-duty applications that demand robust and reliable operation in environments such as manufacturing plants, processing units, and utility facilities.Q: What are the operational benefits of using the LC1F150 contactor in industrial processes?

A: The LC1F150 offers high durability, energy-efficient operation (with a holding consumption of only 12 VA), robust short circuit protection, and low maintenance requirement. These attributes translate to reduced downtime and long-term cost savings for industrial users.Q: How does this contactor ensure safe operation in different environmental conditions?

A: With an IP20 protection rating, flame-retardant housing, vibration resistance (5 gn at 5...300 Hz), and the ability to operate in temperatures from -5C to +60C and humidity up to 95% RH (non-condensing), the LC1F150 is engineered for safety and dependable performance across challenging industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

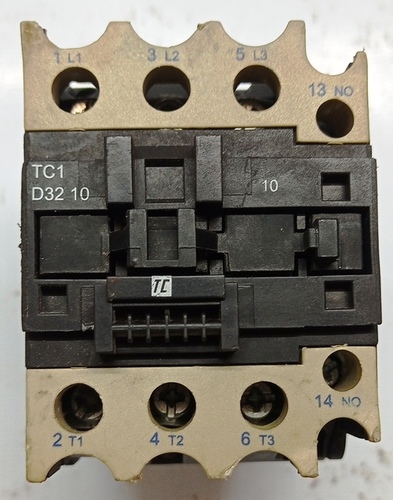

More Products in TC Contactor Category

TELEMECANIQUE TC1D3210 CONTACTOR

Weight : 0.98 kg

Power Factor : 0.8

Feature : Low Power Consumption, High Switching Reliability

Dimension (L*W*H) : 58 x 105 x 120 mm

Connector Type : Screw Type

Operating Temperature : 5°C to +55°C

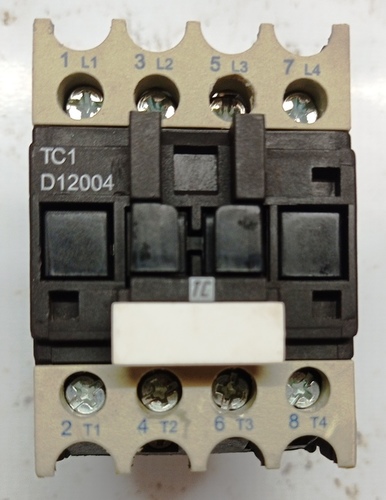

TELEMECANIQUE TC1D12004 CONTACTOR

Weight : 430 g

Power Factor : 0.8

Feature : Compact size, reliable performance, long mechanical life

Dimension (L*W*H) : 45 mm x 77 mm x 82 mm

Connector Type : Screw Type

Operating Temperature : 5°C to +60°C

TELEMECANIQUE LC1D4011 CONTACTOR

Weight : 1.1 kg

Power Factor : 0.8

Feature : Low Power Loss, High Durability

Dimension (L*W*H) : 57mm x 57mm x 98mm

Connector Type : Screw Terminal

Operating Temperature : 5°C to +60°C

TELEMECANIQUE LC1D115 CONTACTOR

Weight : 3.5 kg

Power Factor : 0.85

Feature : High performance, long service life

Dimension (L*W*H) : 139 x 129 x 149 mm

Connector Type : Screw Clamp

Operating Temperature : 5°C to +60°C

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese