Welcome Our Company!

ABB ACS 800 50 HP AC DRIVE

ABB ACS 800 50 HP AC DRIVE Specification

- Feature

- Direct Torque Control (DTC), User-friendly Interface, Programmable

- Mounting Type

- Wall Mounted / Panel Mounted

- Shape

- Rectangular Cabinet

- Surface Finish

- Matte Coated

- Power Factor

- >= 0.95

- Insulation Material

- High Grade Insulating Plastics

- Operating Temperature

- -10C to +40C

- Connector Type

- Screw Terminal

- Efficiency

- Up to 98%

- Overheating Protection

- Integrated Over Temperature Monitoring

- Humidity %

- Max 95%, Non-condensing

- IP Rating

- IP 21

- Product Type

- AC Drive Inverter

- Application

- Industrial Motor Control, HVAC, Pumps, Fans, Conveyors

- Protection Level

- High Protection, Overload and Short Circuit Protected

- Frequency (MHz)

- 50/60 Hz

- Rated Voltage

- 400V AC

- Energy Consumption

- Optimized for Energy Saving

- Output Type

- 3 Phase AC Output

- Color

- Light Grey

- Dimension (L*W*H)

- 270 mm x 535 mm x 310 mm

- Weight

- Approx. 62 kg

- Phase

- Three Phase

- Input Voltage

- 380V - 415V AC

- Size

- 50 HP Rating

- Connection Type

- Terminal Block

- No Of Poles

- Variable (Depends on Motor)

- Material

- Steel & Electronics

ABB ACS 800 50 HP AC DRIVE Trade Information

- Payment Terms

- Cash in Advance (CID)

- Sample Available

- Yes

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About ABB ACS 800 50 HP AC DRIVE

An AC drive is aA device used to control the speed of an electrical motorA in order to: enhance process control. reduce energy usage and generate energy efficiently. decrease mechanical stress on motor control applications.Versatile Motor Control for Industrial Applications

Specially engineered for high-performance environments, the ABB ACS 800 50 HP AC Drive delivers optimal speed and torque control for various industrial motors. Its compatibility with three-phase systems, varied pole configurations, and different application needs-such as HVAC, pumps, and conveyors-ensures adaptability and maximizes operational efficiency.

Comprehensive Communication and Remote Monitoring Options

The ACS 800 features multiple communication ports including RS485 and Modbus as standard, with Profibus offered as an optional upgrade. These robust connectivity options permit seamless integration into existing systems, enabling effective remote monitoring and control-perfect for modern industrial automation and data-driven maintenance.

Reliable Design with User-Focused Features

Built for durability, this drive comes with a sturdy steel and electronics build, high-grade insulation, and an IP21 rating. The large LCD digital keypad simplifies parameter setup, while integrated safety measures-including overload and short circuit protection-provide peace of mind. Easy front panel access streamlines servicing and routine maintenance.

FAQ's of ABB ACS 800 50 HP AC DRIVE:

Q: How does the built-in braking chopper in the ABB ACS 800 enhance motor performance?

A: The integrated braking chopper efficiently dissipates excess regenerative energy during rapid braking, allowing the motor to stop quickly without causing voltage spikes or system instability. This ensures smoother control and extends the lifespan of both the drive and connected equipment.Q: What are the benefits of the various communication ports included with the ACS 800 drive?

A: With standard RS485 and Modbus interfaces-plus optional Profibus-users gain flexible connectivity for integrating with existing automation systems, enabling real-time data exchange, remote monitoring, and streamlined process control. These features are ideal for large-scale industrial operations that prioritize automation and centralized control.Q: When should the drive's integrated safety and protection features be utilized?

A: The ACS 800's overload and short circuit protection, over-temperature monitoring, and high protection level should be relied upon during installation and regular operation to guard against electrical faults, prevent motor damage, and minimize the risk of costly downtime or repairs.Q: Where is the optimal installation location for the ABB ACS 800 drive?

A: This AC drive is designed for wall-mounted or panel-mounted configurations in industrial environments. Ensure installation in a well-ventilated area within an ambient temperature range of -10C to +40C and non-condensing humidity up to 95%, avoiding direct exposure to extreme heat or moisture.Q: What is the process for programming and configuring the ACS 800 drive?

A: Programming is performed through the LCD digital keypad, which features password protection for secure access. The intuitive interface allows users to set parameters, monitor status, and customize operation. PC connectivity enables advanced configuration or firmware updates when necessary.Q: How can accessory options enhance the drive's functionality?

A: Additional modules-such as fieldbus adapters, I/O extensions, and EMC filters-expand the drive's communication capabilities, input/output support, and electromagnetic compatibility. These accessories increase versatility and adaptability for specific application demands.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in AC Drive Category

15 HP FUJI AC DRIVE

Frequency (MHz) : 50/60 Hz

Size : Standard (for 15 HP)

Rated Voltage : 415 V AC

IP Rating : IP20

Material : ABS Plastic Housing, Metal Chassis

Color : Grey

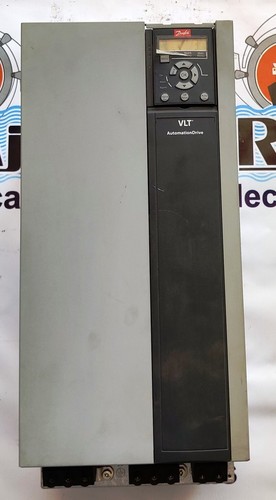

DANFOSS 60 HP AC Drive

Frequency (MHz) : 4763 Hz

Size : 60 HP

Rated Voltage : 380480 V AC

IP Rating : IP21

Material : ABS & Metal Housing

Color : Grey

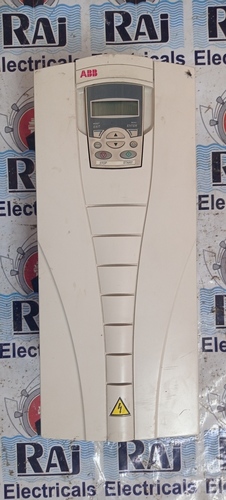

ABB ACS 550 15 HP AC DRIVE

Frequency (MHz) : 50/60 Hz

Size : Wall Mounted Unit

Rated Voltage : 380480 V AC

IP Rating : IP21

Material : ABS Plastic & Metal

Color : White

ABB ACS 550 10 HP AC DRIVE

Frequency (MHz) : 50/60 Hz

Size : 10 HP

Rated Voltage : 380480 VAC

IP Rating : IP21

Material : Steel / ABS Plastic

Color : White/Grey

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese