ABB ACS 550 10 HP AC DRIVE

ABB ACS 550 10 HP AC DRIVE Specification

- Surface Finish

- Powder Coated

- Insulation Material

- ABS Plastic

- Humidity %

- 0-95% non-condensing

- Feature

- User-friendly interface, integrated EMC filter

- Shape

- Rectangular

- Overheating Protection

- Built-in thermal protection

- Power Factor

- 0.98

- Operating Temperature

- -10C to +50C

- Efficiency

- Up to 98%

- IP Rating

- IP21

- Connector Type

- Screw Terminal Block

- Mounting Type

- Wall/Panel Mount

- Product Type

- AC Drive

- Application

- Industrial Motor Control

- Protection Level

- Overload, Short Circuit, Overvoltage

- Frequency (MHz)

- 50/60 Hz

- Rated Voltage

- 380-480 VAC

- Energy Consumption

- High efficiency, low consumption

- Output Type

- Variable Frequency AC

- Color

- White/Grey

- Dimension (L*W*H)

- 128 x 188 x 328 mm

- Weight

- 7.5 kg

- Phase

- Three Phase

- Size

- 10 HP

- Input Voltage

- 380-415 VAC

- No Of Poles

- 3

- Material

- Steel / ABS Plastic

- Connection Type

- Screw Terminal

- Cooling Type

- Forced Air

- Control Method

- V/Hz, Vector Control

- Ambient Altitude

- Max. 1000 m without derating

- Communication Interface

- Modbus, RS-485

- Analog Inputs

- 2 (0-10V, 4-20mA)

- Storage Temperature

- -40°C to +70°C

- Drive Model

- ACS550-01-012A-4

- Max Output Current

- 12 Amps

- Noise Level

- <70 dB

- Display Type

- LCD Graphical Keypad

- Braking Chopper

- Integrated

- Digital Inputs

- 6 programmable

- Motor Power

- 10 HP (7.5 kW)

- Relay Outputs

- 3 programmable

ABB ACS 550 10 HP AC DRIVE Trade Information

- Payment Terms

- Cash in Advance (CID)

- Sample Available

- Yes

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About ABB ACS 550 10 HP AC DRIVE

An AC drive is a device used to control the speed of an electrical motor in order to: enhance process control. reduce energy usage and generate energy efficiently. decrease mechanical stress on motor control applications.Advanced Motor Control and Efficiency

Designed for three-phase motors, the ACS 550 optimizes energy consumption through its high efficiency rating and variable frequency output. Its integrated user interface and programmable inputs streamline operation, while built-in protection features safeguard equipment from overloads and electrical faults.

Versatile Installation and Connectivity

This drive supports wall or panel mounting, allowing flexible deployment across varied industrial environments. Multiple analog and digital inputs, alongside RS-485 Modbus communication, facilitate tailored system integration and remote monitoring, enhancing process performance and data accessibility.

FAQ's of ABB ACS 550 10 HP AC DRIVE:

Q: How can I install the ABB ACS 550 10 HP AC Drive in my facility?

A: The ACS 550 is designed for easy wall or panel mounting using its screw terminal block connectors. Ensure proper ventilation and comply with the ambient temperature and altitude specifications for optimal operation. Detailed installation instructions are provided in the user manual.Q: What control methods does this drive support for motor regulation?

A: It supports both V/Hz and Vector Control methods, allowing precise regulation of motor speed and torque according to your specific process requirements. Users can select the control mode via the integrated graphical keypad for tailored performance.Q: When should I use the integrated braking chopper feature?

A: The integrated braking chopper should be utilized during rapid deceleration or stopping of the motor, especially in applications requiring quick, controlled dissipation of kinetic energy without external braking resistors.Q: Where can this AC drive be deployed for industrial use?

A: This drive is suitable for a wide range of industrial settings managing three-phase motors, particularly in environments up to 1000 m altitude. Its IP21-rated enclosure and powder-coated finish provide durability in demanding production areas.Q: What is the process for programming the digital and relay outputs?

A: Programming is done through the LCD graphical keypad, allowing customization of six digital inputs and three relay outputs. The user-friendly interface supports easy assignment of control functions and process signals according to your application needs.Q: What benefits does the ACS 550 offer in terms of energy efficiency?

A: The drive delivers up to 98% efficiency and maintains a high power factor of 0.98, resulting in reduced energy consumption, lower operating costs, and enhanced overall system performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in AC Drive Category

YASKAWA 25 HP AC Drive

Dimension (L*W*H) : 320 x 220 x 250 mm

Weight : 38 kg

Protection Level : Other, Overload, Overcurrent, Short Circuit

Energy Consumption : High Efficiency

Mounting Type : Panel / Wall Mounted

Connection Type : Terminal Block

ABB ACS 800 150 HP AC DRIVE

Dimension (L*W*H) : 650 mm x 300 mm x 350 mm

Weight : 225 kg

Protection Level : Other, High

Energy Consumption : Optimized, Low Loss

Mounting Type : Panel Mounted

Connection Type : Terminal Block

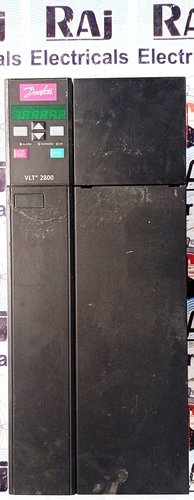

DANFOSS VLT 2800 30 HP AC DRIVE

Dimension (L*W*H) : 260 mm x 90 mm x 242 mm

Weight : 11.5 kg

Protection Level : Other, Overload, shortcircuit, overvoltage

Energy Consumption : High efficiency, energy optimized

Mounting Type : Wall mount

Connection Type : Terminal Block

ABB ACS 800 200 HP AC DRIVE

Dimension (L*W*H) : 650 x 400 x 320 mm

Weight : Approx. 235 kg

Protection Level : Other, Overvoltage, Undervoltage, ShortCircuit

Energy Consumption : High Efficiency Operation

Mounting Type : Floor/Panel Mounted

Connection Type : Hardwired Terminals

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese