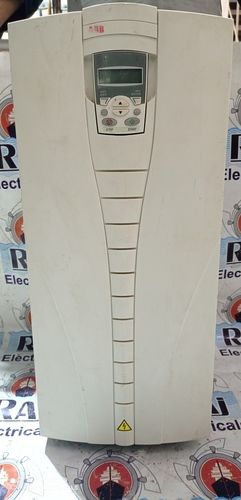

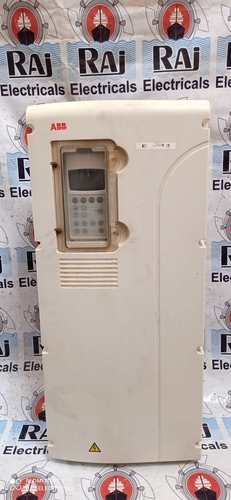

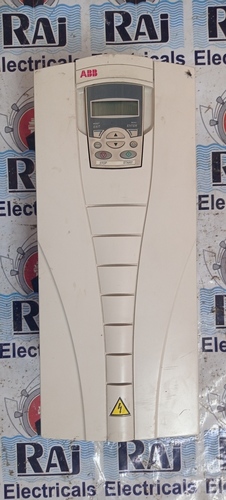

ABB ACS 800 100 HP AC DRIVE

ABB ACS 800 100 HP AC DRIVE Specification

- IP Rating

- IP21 / IP54 (as per model)

- Power Factor

- >= 0.95

- Overheating Protection

- Yes, Overtemperature Alarm and Trip

- Mounting Type

- Floor or Wall Mounted

- Operating Temperature

- -10C to +45C

- Connector Type

- Screw Terminals / Pluggable

- Shape

- Rectangular

- Insulation Material

- Thermoplastic, Sheet Metal

- Humidity %

- 5% to 95% (non-condensing)

- Feature

- Vector Control, Built-in Harmonic Filter, PID Control, Programmable Inputs/Outputs

- Surface Finish

- Powder Coated

- Efficiency

- >= 97%

- Product Type

- AC Drive

- Application

- Industrial Automation, Motor Control

- Protection Level

- High (Integrated Safety Features)

- Frequency (MHz)

- 50-60 Hz

- Rated Voltage

- 415V AC

- Energy Consumption

- Optimized for High Efficiency Operation

- Output Type

- Three Phase AC

- Color

- White / Light Grey

- Dimension (L*W*H)

- Height: 1780 mm; Width: 550 mm; Depth: 400 mm

- Weight

- 180 kg

- Size

- Standard, Suits 100 HP Motor

- Input Voltage

- 380-500V AC, Three Phase

- Phase

- Three Phase

- Connection Type

- Panel Mounted, Cable Input/Output

- Material

- Sheet Metal, Electronic Components

- Serviceability

- Modular Design for Easy Maintenance

- Safety Standards

- IEC/EN 61800-5-1

- Control Method

- Vector Control, Direct Torque Control (DTC)

- Fault Logging

- Event and Error Diagnosis Memory

- Braking Option

- Built-In Dynamic Braking

- Altitude

- Up to 2000 m without Derating

- Storage Temperature Range

- -25°C to +70°C

- Display Type

- LCD Digital Display

- Noise Level

- <68 dB(A)

- Start-Up Assist

- Automatic Motor Adaptation

- Communication Ports

- RS485, Modbus, Profibus Optional

- Programming Interface

- Keypad and PC Software

- Cooling Method

- Forced Air Cooling

- Maximum Output Current

- 150 A

- Motor Compatibility

- Asynchronous and Synchronous Motors

ABB ACS 800 100 HP AC DRIVE Trade Information

- Payment Terms

- Cash in Advance (CID)

- Sample Available

- Yes

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About ABB ACS 800 100 HP AC DRIVE

An AC drive is a device used to control the speed of an electrical motor in order to: enhance process control. reduce energy usage and generate energy efficiently. decrease mechanical stress on motor control applications.Advanced Motor Control for Industrial Automation

The ABB ACS 800 AC Drive utilizes Vector Control and Direct Torque Control (DTC) for superior performance in industrial automation. These control methods optimize torque, speed response, and process reliability, supporting both standard and demanding applications. With compatibility for both asynchronous and synchronous motors, industries experience flexible integration and smooth operation.

Efficient and User-Friendly Operation

Designed for efficiency and ease of use, the ACS 800 features an LCD digital display, programmable keypad, and PC software interface. Built-in harmonic filter and PID control further enhance energy savings and process stability, while robust event and error diagnosis provide prompt fault logging and serviceability. Its modular design enables convenient maintenance and reduced downtime.

Safety, Protection, and Durability

Meeting IEC/EN 61800-5-1 safety standards, this drive ensures high-level protection with integrated safety functions, overheating alarms, and rugged sheet metal construction. The IP21/IP54 protection rating and wide temperature/humidity range support reliable operation in diverse environments. Its powerful dynamic braking and insulation materials guarantee durability and long equipment life.

FAQs of ABB ACS 800 100 HP AC DRIVE:

Q: How does the ABB ACS 800 100 HP AC Drive support precise motor control?

A: The drive employs Vector Control and Direct Torque Control (DTC) technologies, enabling highly accurate speed and torque regulation for both asynchronous and synchronous motors, which is essential for applications requiring consistent performance and control.Q: What are the communication and programming options available on this drive?

A: It offers robust communication with built-in RS485, supporting Modbus, and optional Profibus interfaces. Programming can be done via a user-friendly keypad or PC software, allowing for flexible monitoring and configuration to suit diverse industrial needs.Q: When should I use the built-in dynamic braking feature?

A: Dynamic braking is useful during rapid stops or deceleration phases, particularly in applications with high inertia loads. It engages automatically, providing effective energy dissipation and maintaining system safety, especially during emergencies or quick cycle operations.Q: Where can the ABB ACS 800 drive be installed, and what are its mounting options?

A: The drive is designed for versatile installation, suitable for either floor or wall mounting, and features a panel-mounted, cable input/output connection. Its IP21/IP54 rated enclosures support use in various industrial settings, including high-dust or high-moisture environments.Q: What processes does the drive optimize for energy efficiency and reliability?

A: Integrated PID control, automatic motor adaptation, and a built-in harmonic filter contribute to optimized energy consumption and high operational efficiency (97%). Its advanced error diagnosis and modular design also simplify maintenance, minimizing downtime.Q: How does this AC drive benefit industrial automation applications?

A: The ACS 800 enhances process reliability, improves motor control precision, and ensures maximum energy efficiency. Its high protection level, comprehensive diagnostic capabilities, and flexible integration options make it a valuable asset for sustainable and uninterrupted industrial automation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in AC Drive Category

ABB ACS 550 60 HP AC DRIVE

Product Type : AC Drive (Variable Frequency Drive)

Power Factor : >0.98

Connection Type : Screw Terminal

IP Rating : IP21

Operating Temperature : 10C to +50C

Weight : 31 kg

ABB ACS 800 60 HP AC DRIVE

Product Type : AC Variable Frequency Drive

Power Factor : >0.97

Connection Type : Screw Terminal

IP Rating : IP21 (standard), IP54 (optional)

Operating Temperature : 10C to +40C without derating

Weight : Approximately 87 kg

ABB ACS 550 15 HP AC DRIVE

Product Type : AC Drive

Power Factor : >=0.95

Connection Type : Screw Terminal

IP Rating : IP21

Operating Temperature : 10C to +50C

Weight : 9.2 kg

Telemecanique ATV31

Product Type : AC Variable Frequency Drive

Power Factor : 0.98

Connection Type : Terminal

IP Rating : IP20

Operating Temperature : 10C to +50C

Weight : 1.3 kg

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese