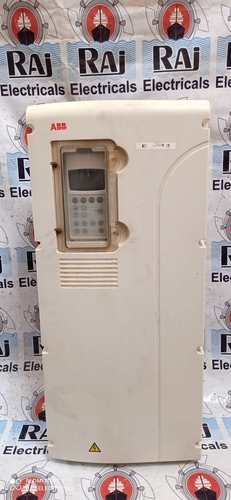

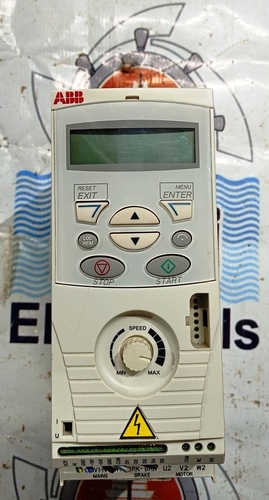

ABB ACS 800 60 HP AC DRIVE

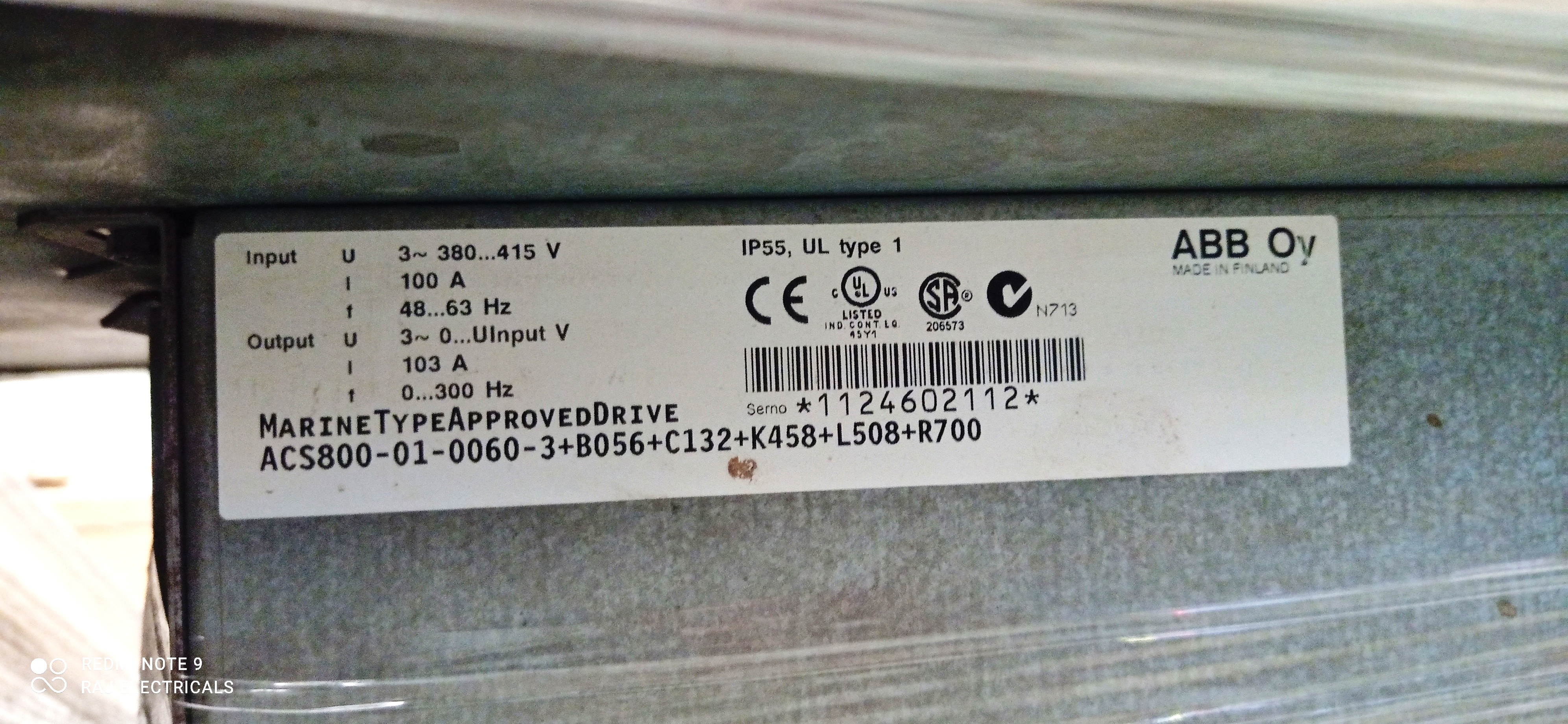

ABB ACS 800 60 HP AC DRIVE Specification

- Efficiency

- up to 98%

- IP Rating

- IP21 (standard), IP54 (optional)

- Power Factor

- >0.97

- Humidity %

- 0-95% RH, non-condensing

- Operating Temperature

- -10C to +40C without derating

- Feature

- Direct Torque Control (DTC), Programmable, User-friendly Interface

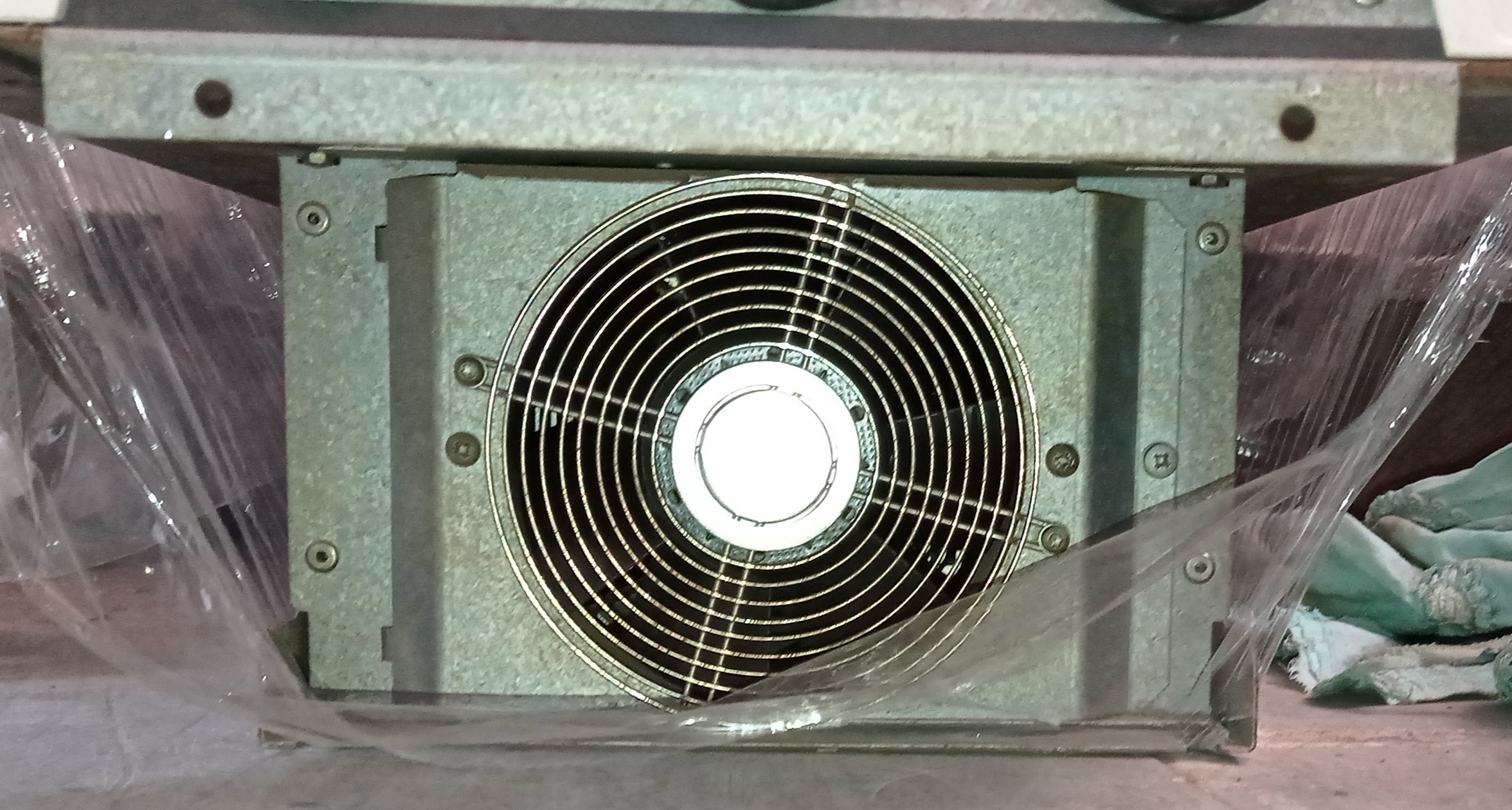

- Overheating Protection

- Integrated Thermal Protection

- Mounting Type

- Wall Mounted

- Shape

- Rectangular

- Insulation Material

- High Grade Polymer, Insulated Metal Parts

- Surface Finish

- Powder Coated

- Connector Type

- Screw and Plug Connections

- Product Type

- AC Variable Frequency Drive

- Application

- Industrial Motor Speed Control

- Protection Level

- Advanced Overcurrent, Short Circuit, and Overvoltage protection

- Frequency (MHz)

- 50/60 Hz

- Rated Voltage

- 400 V AC

- Energy Consumption

- Optimized with energy-saving algorithms

- Output Type

- Three Phase Output

- Color

- White/Grey

- Dimension (L*W*H)

- 568 mm x 284 mm x 309 mm (HxWxD)

- Weight

- Approximately 87 kg

- Size

- 60 HP (45 kW)

- Phase

- Three Phase

- Input Voltage

- 380-480 V AC

- No Of Poles

- 3

- Connection Type

- Screw Terminal

- Material

- Metal (Steel Body), Plastics

ABB ACS 800 60 HP AC DRIVE Trade Information

- Payment Terms

- Cash in Advance (CID)

- Sample Available

- Yes

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About ABB ACS 800 60 HP AC DRIVE

An AC drive is a device used to control the speed of an electrical motor in order to: enhance process control. reduce energy usage and generate energy efficiently. decrease mechanical stress on motor control applications.Versatile Motor Control and Performance

The ABB ACS800 supports both Scalar (V/f) and advanced Direct Torque Control (DTC), ensuring precise and responsive speed and torque control for a wide range of motor types. Its compatibility with both asynchronous and synchronous motors makes it a flexible choice for industrial motor speed control applications.

Integrated Safety and Reliability

Safety is paramount with the built-in Safe Torque Off (STO) function, protecting both personnel and equipment. Additional features such as advanced overcurrent, short circuit, and overvoltage protection enhance system reliability, while robust construction and thermal management extend product life.

Flexible Connectivity and Easy Operation

Equipped with RS485, Modbus, and optional Profibus interfaces, the ACS800 integrates seamlessly into modern control systems. The user-friendly alphanumeric LCD keypad simplifies programming and monitoring, and extensive analog/digital I/O allows for versatile process adaptation and control.

FAQ's of ABB ACS 800 60 HP AC DRIVE:

Q: How do I connect the ABB ACS800 60 HP AC Drive to my control system?

A: The drive can be integrated via RS485, Modbus, or optional Profibus communication, enabling straightforward connection to many industrial automation systems. Screw terminal and plug connections are provided for hassle-free wiring.Q: What are the primary benefits of using Direct Torque Control (DTC) with this drive?

A: DTC provides precise, real-time torque and speed performance, minimizing response times and improving energy efficiency. This results in optimal process control, reduced motor wear, and more consistent production quality.Q: When should I consider using the integrated dynamic braking feature?

A: The dynamic braking (internal chopper) is ideal for applications requiring rapid deceleration or stopping, such as conveyors, cranes, or high-inertia machinery. It helps dissipate excess energy, preventing drive overvoltage and enhancing safety.Q: Where can I access the drive's settings and monitor its performance?

A: You can configure and monitor the ACS800 through the alphanumeric LCD keypad on the front panel. Additionally, remote access is possible via fieldbus communication interfaces, enhancing maintenance flexibility.Q: What is the process for programming custom logic functions in the ACS800?

A: The drive features built-in programmable logic capabilities. Using the keypad or dedicated software, users can create and customize logic sequences for tailored automation, eliminating the need for external controllers in many scenarios.Q: How does the integrated EMC filtering benefit my installation?

A: The built-in EMC filter reduces electrical noise emissions, helping your installation meet regulatory compliance and protecting sensitive equipment nearby from electromagnetic interference.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in AC Drive Category

Abb Acs 550

Efficiency : Up to 98%

Protection Level : Other, Overload, Short Circuit

Color : White/Grey

Application : Industrial Automation, Motor Control

Output Type : Variable Frequency Drive

Humidity % : 595% (noncondensing)

ABB ACS 150 1 HP AC DRIVE

Efficiency : Up to 97%

Protection Level : Other, Overload, Overcurrent, Short Circuit

Color : White/Grey

Application : Industrial Automation, Motor Speed Control

Output Type : Analog (Variable Voltage and Frequency)

Humidity % : 5% to 95% (noncondensing)

ABB ACS 550 150 HP AC DRIVE

Efficiency : Up to 98%

Protection Level : Other, Overvoltage, Undervoltage, Overcurrent, Short Circuit, Ground Fault

Color : Off White

Application : Industrial Motor Control, Pump, Fan, Conveyor, HVAC

Output Type : Three Phase Output

Humidity % : 5 to 95% (noncondensing)

ABB ACS 800 125 HP AC DRIVE

Efficiency : >97%

Protection Level : Other, Overload, Short Circuit, Ground Fault, Overvoltage

Color : Light Grey

Application : Industrial motor control, pumps, fans, conveyors

Output Type : 3phase AC

Humidity % : 5% to 95%, noncondensing

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese