Abb Acs 550

Abb Acs 550 Specification

- Connector Type

- Terminal Block

- Humidity %

- 5-95% (non-condensing)

- Surface Finish

- Matte

- Operating Temperature

- -10C to +50C

- Shape

- Rectangular

- Insulation Material

- Polycarbonate

- Feature

- Integrated EMC Filter, Built-in Brake Chopper

- IP Rating

- IP21

- Efficiency

- Up to 98%

- Overheating Protection

- YES

- Mounting Type

- Wall Mount

- Power Factor

- 0.98

- Product Type

- AC Drive

- Application

- Industrial Automation, Motor Control

- Protection Level

- Overload, Short Circuit

- Frequency (MHz)

- 50/60 Hz

- Rated Voltage

- 400 V AC

- Energy Consumption

- High Efficiency

- Output Type

- Variable Frequency Drive

- Color

- White/Grey

- Dimension (L*W*H)

- 423 125 203 mm

- Weight

- 15 kg

- Phase

- Three Phase

- Input Voltage

- 380-480 V AC

- Size

- Standard

- Connection Type

- Screw Terminal

- No Of Poles

- 3

- Material

- Plastic, Metal

Abb Acs 550 Trade Information

- Payment Terms

- Cash in Advance (CID)

- Sample Available

- Yes

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Abb Acs 550

Abb Acs 550

The ABB ACS 550 AC drive combines a sophisticated micro- processor with an advanced IGBT power switching technol- ogy to deliver V/Hz, Closed Loop Flux Vector and Sensorless Vector control of AC motors. Its intuitive control panel offers numerous benefits making it the most user-friendly panel in the drives industry .WE DEAL ALL TYPES OF ABB AC DRIVES FROM 5 HP TO 200 HP

Advanced Motor Control Solutions

The ABB ACS 550 provides dynamic motor control options, offering both scalar (V/Hz) and sensorless vector control techniques. This adaptability enables users to achieve optimal performance, energy savings, and process consistency across a wide variety of industrial automation tasks.

Integrated Safety and Efficiency

With overload, short circuit, and overheating protection, as well as an integrated brake chopper and EMC filter, the ACS 550 ensures safe, efficient operation. It operates efficiently up to 98%, reducing energy consumption, and its power factor of 0.98 further enhances operational efficiency.

User-Friendly Design and Connectivity

An intuitive LCD control panel with keypad programming makes setup and monitoring simple. Remote operation and Modbus/RS485 communication support seamless integration with existing control systems. Wall-mounted installation, forced cooling, and IP21 enclosure allow for reliable use in a variety of industrial environments.

FAQ's of Abb Acs 550:

Q: How does the ABB ACS 550 improve motor control in industrial applications?

A: The ABB ACS 550 offers both scalar (V/Hz) and sensorless vector control methods, giving users enhanced precision and energy efficiency in motor management. This flexibility allows for stable operation and adaptability across various load types in industrial automation.Q: What is the installation process for the ACS 550, and where can it be mounted?

A: The ACS 550 is designed for straightforward wall mounting using a screw terminal connection type. Its IP21 rating and forced fan cooling system make it suitable for installation in protected indoor industrial environments, ensuring consistent operation between -10C and +50C.Q: When should the built-in braking unit and brake chopper be utilized?

A: The integrated braking unit and brake chopper should be used when rapid deceleration or stopping of the motor is required, especially in applications with high inertia loads. This feature helps dissipate excess energy safely, maintaining system performance and protection.Q: What are the main communication options for remote operation and integration?

A: The ACS 550 supports Modbus and RS485 communication protocols, allowing seamless integration into existing industrial networks. This facilitates remote monitoring, control, and real-time diagnostics to maximize process efficiency and uptime.Q: How does the ACS 550 ensure safety and protection for motors and connected systems?

A: The ACS 550 is equipped with overload, short circuit, and overheating protection systems. These features, along with precise control and an integrated EMC filter, safeguard both the drive and the connected motor from operational hazards commonly encountered in industrial settings.Q: What benefits does the high efficiency of the ACS 550 offer to users?

A: Operating at up to 98% efficiency and a power factor of 0.98, the ACS 550 reduces overall energy consumption, which leads to lower operating costs. It also contributes to a more sustainable production process, aligning with energy-saving initiatives in modern industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in AC Drive Category

TELEMECANIQUE (Altivar-61) 50 HP AC DRIVE

IP Rating : IP 20

Feature : EMC Filter, Integrated PID, User Friendly Interface

Overheating Protection : Other, Yes (Thermal Protection)

Efficiency : Up to 98%

Input Voltage : 380480V AC, 3 Phase

Color : Grey / Blue

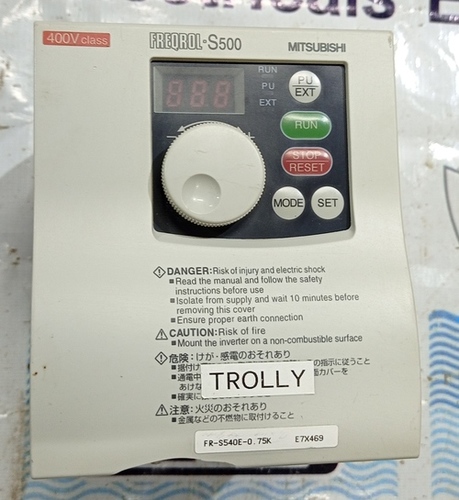

Mitsubishi 1 Hp Ac Drive

IP Rating : IP20

Feature : Variable Speed Drive, Soft Start, Energy Efficient

Overheating Protection : YES

Efficiency : >= 95%

Input Voltage : 220240 V AC

Color : Black & Grey

ABB ACS 550 75 HP AC DRIVE

IP Rating : IP21

Feature : Intuitive Keypad, Builtin EMC Filter, PID Control, Vector Control

Overheating Protection : YES

Efficiency : >97%

Input Voltage : 380480 V AC

Color : White & Grey

MITSUBISHI Ac Drive 15 HP

IP Rating : IP20

Feature : Builtin EMC filter, Automatic Torque Boost, Userfriendly Interface

Overheating Protection : YES

Efficiency : >=98%

Input Voltage : 380480V AC, 3 Phase

Color : Grey

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese