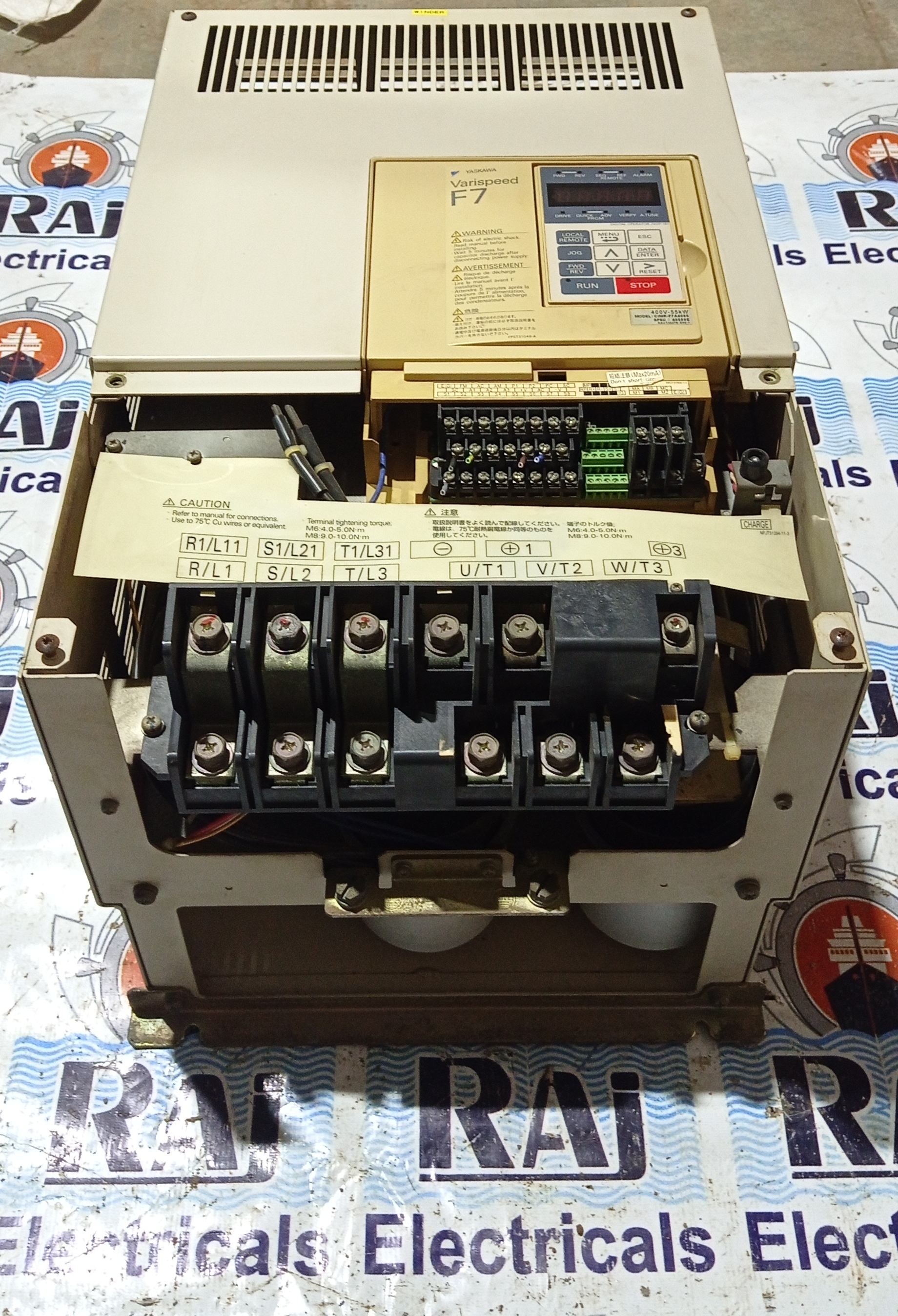

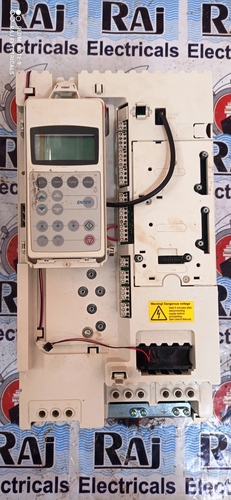

YASKAWA VARISPEED F7 50 HP AC DRIVE

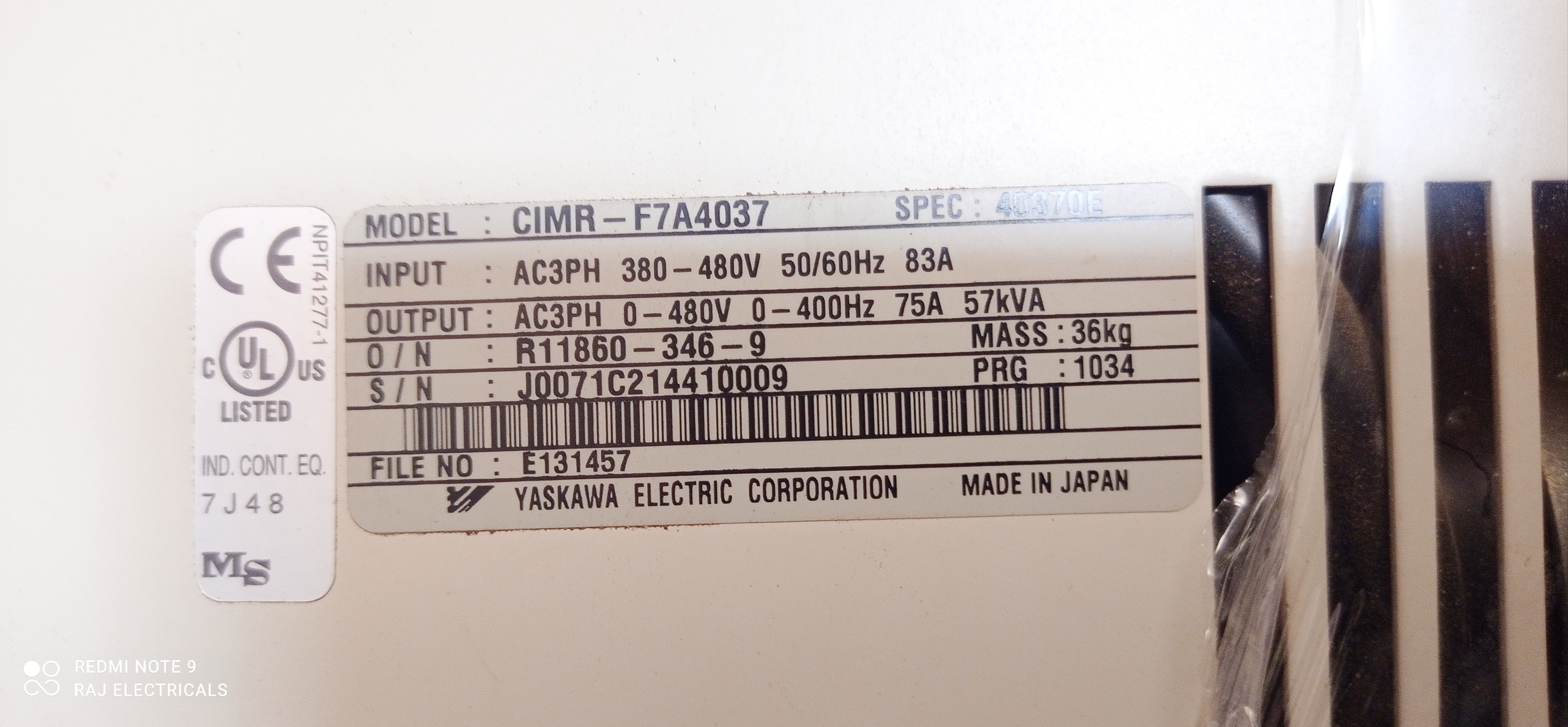

YASKAWA VARISPEED F7 50 HP AC DRIVE Specification

- Mounting Type

- Wall Mount

- IP Rating

- IP20

- Connector Type

- Terminal Block

- Overheating Protection

- YES

- Shape

- Rectangular

- Feature

- Vector Control, Auto-tuning, Built-in Filter

- Surface Finish

- Powder Coated

- Humidity %

- Max. 90% (non-condensing)

- Efficiency

- >95%

- Power Factor

- >0.95

- Insulation Material

- Class F

- Operating Temperature

- -10C to +50C

- Product Type

- AC Drive

- Application

- Industrial Automation, Motor Control

- Protection Level

- Overload, Overcurrent, Short Circuit

- Frequency (MHz)

- 50/60 Hz

- Rated Voltage

- 380-480 V AC

- Energy Consumption

- High Efficiency

- Output Type

- Adjustable Frequency & Voltage

- Color

- Gray

- Dimension (L*W*H)

- 380 x 250 x 220 mm

- Weight

- 27 kg

- Input Voltage

- 380-480 V AC

- Size

- Standard

- Phase

- Three Phase

- Connection Type

- Panel Mount

- Material

- ABS Plastic & Metal

- No Of Poles

- 3

- Overload Capacity

- 150% for 60 seconds

- Altitude

- Up to 1000 m without derating

- Communication

- RS-485 (Modbus), Optional Fieldbus Modules

- Cooling Method

- Forced Air Cooling (Fan Assisted)

- Braking Unit

- Integrated

- Model Number

- VARISPEED F7 (CIMR-F7A4037)

- Maximum Output Frequency

- 400 Hz

- Regenerative Braking

- Optional (External Unit Required)

- Display Type

- LED / LCD Digital Keypad

- Output Power

- 37 kW / 50 HP

- Control Method

- V/F Control, Sensorless Vector Control, Closed Loop Vector Control

- Enclosure Type

- Open Type (IP20)

- Noise Level

- Less than 70 dB

YASKAWA VARISPEED F7 50 HP AC DRIVE Trade Information

- Payment Terms

- Cash in Advance (CID)

- Sample Available

- Yes

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About YASKAWA VARISPEED F7 50 HP AC DRIVE

An AC drive is a device used to control the speed of an electrical motor in order to: enhance process control. reduce energy usage and generate energy efficiently. decrease mechanical stress on motor control applications. optimize the operation of various applications relying on electric motorsSophisticated Motor Control for Versatile Applications

The VARISPEED F7 is equipped with advanced control methodsV/F, Sensorless Vector, and Closed Loop Vector Controlcatering to diverse automation requirements. Its built-in protections and high efficiency ensure optimal operation in industrial settings, maximizing productivity and process reliability. Adaptable to many motor types and suited for demanding loads, it delivers stable performance with adjustable frequency and voltage outputs.

User-Friendly Interface and Installation

Featuring a bright LED/LCD digital keypad, the drive simplifies configuration and monitoring. Its open type (IP20) enclosure allows for straightforward panel or wall mounting, while terminal block connectors make integration hassle-free. The compact, standard size and lightweight design (27 kg) save space and provide flexibility in installation, supporting a variety of system architectures.

Durability, Safety, and Enhanced Connectivity

Constructed from robust ABS plastic and metal with a powder-coated surface, the VARISPEED F7 withstands industrial environments. It incorporates overload, overcurrent, overheating, and short circuit protection for safe, long-term operation. With RS-485 Modbus and optional fieldbus module support, it seamlessly integrates into modern automation networks, ensuring consistent communication and process control.

FAQs of YASKAWA VARISPEED F7 50 HP AC DRIVE:

Q: How does the YASKAWA VARISPEED F7 optimize motor performance in industrial applications?

A: The VARISPEED F7 maximizes motor performance through advanced control methods such as V/F Control, Sensorless Vector Control, and Closed Loop Vector Control. These features allow for precise speed, torque, and position adjustment, adapting to varying load requirements and ensuring high efficiency and reliability in demanding automation environments.Q: What is the recommended process for installing the VARISPEED F7 AC Drive?

A: To install the VARISPEED F7, first securely mount the unit to a wall or panel using the provided mountings. Connect input and output terminals according to the wiring diagram, then configure parameters using the digital keypad. Ensure all safety protocols are observed during installation, and confirm that ambient conditions such as temperature and humidity are within specified limits.Q: When should regenerative braking be used with this drive?

A: Regenerative braking should be used when your application requires rapid deceleration or frequent stop-and-start motion. While the drive has an integrated braking unit, for full regenerative capacity, an external regenerative unit is recommended. This feature is particularly beneficial in applications like cranes, conveyors, or centrifuges where excess energy needs to be safely dissipated or redirected.Q: Where can the VARISPEED F7 AC Drive be deployed for optimal performance?

A: The VARISPEED F7 is ideal for deployment in industrial automation settings such as manufacturing plants, HVAC systems, conveyor lines, and pump/motor control installations. It operates efficiently up to 1000 meters altitude without derating and in temperatures from -10C to +50C, making it suitable for most indoor industrial environments.Q: How does the built-in communication feature enhance usage and integration?

A: The RS-485 Modbus communication port and optional fieldbus modules enable seamless integration with a wide range of industrial networks and programmable logic controllers (PLCs). This connectivity improves process monitoring, remote control, and data exchange, streamlining automation and supporting smart manufacturing initiatives.Q: What are the primary benefits of using the VARISPEED F7 50 HP AC Drive?

A: Key benefits include high energy efficiency (>95%), robust overload and fault protection, flexible mounting and connection options, advanced motor control capabilities, and ease of integration with existing automation systems. Its reliable performance prolongs equipment life and supports productivity in industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in AC Drive Category

YASKAWA VARISPEED F7 150 HP AC DRIVE

Application : Industrial Motor Control, HVAC Systems, Pumps, Fans, Conveyors

Protection Level : Other, Overcurrent, Overvoltage, Undervoltage, Short Circuit, Ground Fault

Efficiency : Up to 98%

Power Factor : 0.98

Product Type : AC Drive

Insulation Material : Thermoplastic Insulation

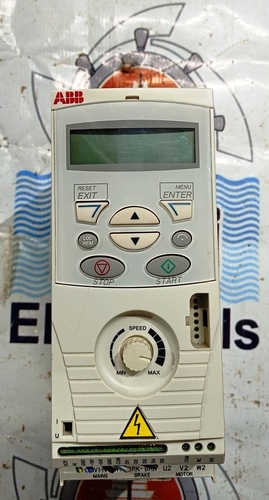

ABB ACS 150 1 HP AC DRIVE

Application : Industrial Automation, Motor Speed Control

Protection Level : Other, Overload, Overcurrent, Short Circuit

Efficiency : Up to 97%

Power Factor : >=0.98

Product Type : AC Drive

Insulation Material : Thermoplastic

MITSUBISHI Ac Drive 15 HP

Application : Industrial Automation, Motor Speed Control, HVAC, Pumps, Fans

Protection Level : Other, Overload, Overvoltage, Undervoltage, Short Circuit

Efficiency : >=98%

Power Factor : >=0.95

Product Type : AC Drive / Variable Frequency Drive

Insulation Material : High Grade Insulation

ABB ACS 800 40 HP AC DRIVE

Application : Industrial Automation, Motor Control

Protection Level : IP54

Efficiency : 98%

Power Factor : 0.98

Product Type : AC Drive

Insulation Material : Highgrade Polymer

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese