Telemecanique ATV31

Telemecanique ATV31 Specification

- Mounting Type

- Panel Mount

- Feature

- Short circuit protection, overvoltage and undervoltage protection

- Humidity %

- 5-95% (non-condensing)

- Efficiency

- Up to 97%

- Shape

- Rectangular

- Insulation Material

- Polycarbonate

- Power Factor

- 0.98

- Connector Type

- Screw/Terminal

- Operating Temperature

- -10C to +50C

- IP Rating

- IP20

- Overheating Protection

- YES

- Surface Finish

- Smooth

- Product Type

- AC Variable Frequency Drive

- Application

- Industrial Motor Control

- Protection Level

- IP20

- Frequency (MHz)

- 50/60 Hz

- Rated Voltage

- 380-480V AC

- Energy Consumption

- Efficient (depends on connected load)

- Output Type

- Three Phase Output

- Color

- Gray / Blue

- Dimension (L*W*H)

- 143 x 72 x 152 mm

- Weight

- 1.3 kg

- Size

- ATV31HU22N4

- Input Voltage

- 380-480V AC

- Phase

- Three Phase

- Material

- Plastic and Metal

- Connection Type

- Terminal

- No Of Poles

- 3

About Telemecanique ATV31

The Altivar 31 (ATV31) family of adjustable frequency AC drive controllers isused for controlling three-phase asynchronous motors. The controllersrange from:0.25 to 3 hp (0.18 to 2.2 kW), 208/230/240 V, single-phase input

0.25 to 20 hp (0.18 to 15 kW), 208/230/240 V, three-phase input

0.5 to 20 hp (0.37 to 15 kW), 400/460/480 V, three-phase input

1 to 20 hp (0.75 to 15 kW), 525/575/600 V, three-phase input

Some ATV31 controllers are available with a reference potentiometer, a runbutton, and a stop/reset button. These controllers are designated asATV31A controllers throughout this manual. The symbol in a catalognumber designates parts of the number that vary with rating.

Reliable Motor Control for Industrial Applications

The ATV31HU22N4 is tailored for demanding industrial environments, supporting three-phase motors with adjustable frequency from 0.5 to 400 Hz. With fan cooling and advanced insulation, it delivers stable performance across a wide temperature range. The units protective features ensure safe operation and longevity for your equipment.

User-Friendly Panel Mount and Operation

This model boasts a compact rectangular design for easy panel mounting. Its intuitive LED numeric display aids in setup and real-time monitoring, while screw/terminal connections facilitate straightforward wiring. Users benefit from smooth surface finish and reliable Modbus communication for networked control.

Efficiency Meets Compliance

The drive adheres to rigorous international standards (IEC/EN 61800-5-1, IEC/EN 61800-3), ensuring both safety and functional reliability. With an efficiency of up to 97% and a power factor of 0.98, it reduces energy consumption according to motor load, making it an excellent choice for cost-conscious operations.

FAQs of Telemecanique ATV31:

Q: How does the Telemecanique ATV31HU22N4 contribute to efficient motor control in industrial settings?

A: The ATV31HU22N4 utilizes V/F (Voltage/Frequency) control to regulate motor speed and torque based on demand, allowing for energy-efficient operation and reduced wear on equipment. Its built-in safeguards further enhance operational reliability.Q: What steps are involved in installing this variable frequency drive on my panel?

A: Installation requires mounting the drive using its panel mount design, connecting input and output terminals, and configuring settings via the LED numeric display. Ensure input voltage matches the 380480V AC requirement for optimal performance.Q: When should I use the integrated braking unit feature?

A: The integrated braking unit should be employed when rapid deceleration of connected motors is needed, particularly in high-inertia applications or emergency stop situations, to safely dissipate energy and protect the system.Q: Where can this drive be effectively utilized in industrial environments?

A: The ATV31HU22N4 is suited for a wide range of industrial motor control operations, including conveyors, pumps, and fans, especially where three-phase motors and precise speed regulation are required.Q: What protection features are provided by the ATV31HU22N4 model?

A: This drive offers multiple protection mechanisms, including short circuit protection, overheating protection, and both overvoltage and undervoltage safeguards, ensuring safe and continuous operation under varying electrical conditions.Q: How do I monitor and adjust operating parameters for optimal performance?

A: Parameters can be easily monitored and adjusted through the LED numeric display and accessed remotely via Modbus communication, providing streamlined configuration and diagnostics for ongoing efficiency.Q: What are the key benefits of choosing this drive for industrial applications?

A: Key advantages include compliance with international standards, high efficiency (up to 97%), versatile input and output options, compact dimensions for easy installation, and robust protection features that enhance longevity and safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in AC Drive Category

HITACHI 250 HP AC DRIVE

Energy Consumption : Optimized for energy efficiency

IP Rating : IP20

Overheating Protection : YES

Rated Voltage : 380480 V AC

Protection Level : Other, Overcurrent, Overvoltage, Undervoltage, Short Circuit Protection

Surface Finish : Powder Coated

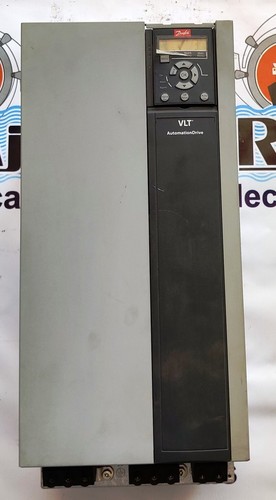

DANFOSS 60 HP AC Drive

Energy Consumption : High Efficiency; Low Power Loss

IP Rating : IP21

Overheating Protection : YES

Rated Voltage : 380480 V AC

Protection Level : Other, Overload, Short Circuit, Overvoltage

Surface Finish : Matte

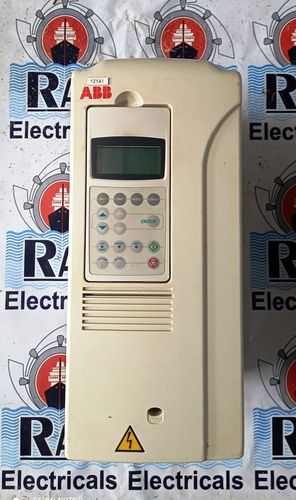

ABB ACS 800 25 HP AC DRIVE

Energy Consumption : High Efficiency Operation

IP Rating : IP21

Overheating Protection : YES

Rated Voltage : 415 V AC

Protection Level : Other, Overload, ShortCircuit, Under Voltage, Over Voltage

Surface Finish : Powder Coated

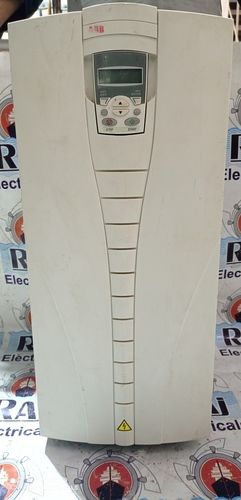

ABB ACS 550 60 HP AC DRIVE

Energy Consumption : High efficiency, Low consumption

IP Rating : IP21

Overheating Protection : Other, Yes, electronic thermal overload

Rated Voltage : 380 480 V AC

Protection Level : Other, Overload, Short Circuit, Ground Fault

Surface Finish : Textured powder coated

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese