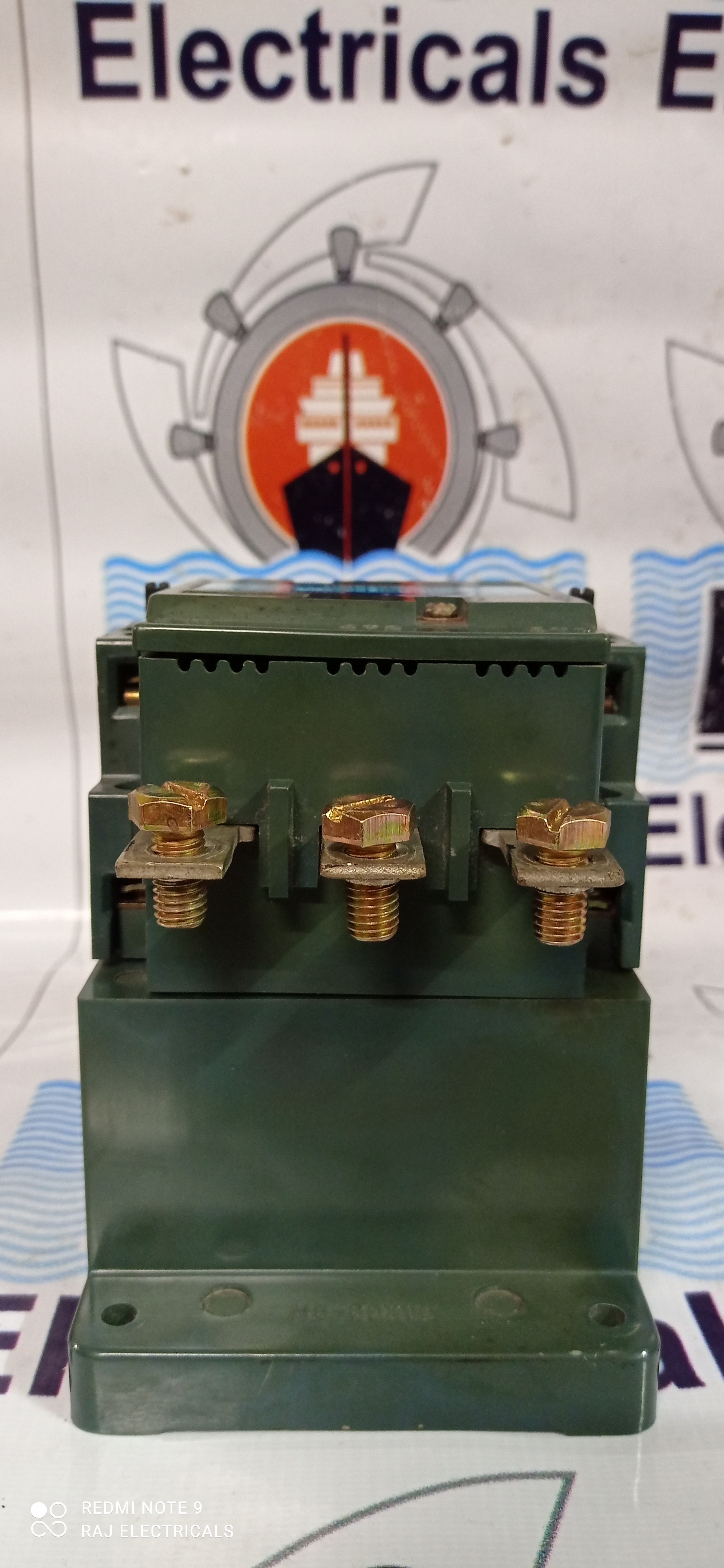

HYUNDAI HMC80 CONTACTOR

HYUNDAI HMC80 CONTACTOR Specification

- Feature

- High Mechanical Durability

- Power Factor

- 0.8

- IP Rating

- IP20

- Insulation Material

- Thermoplastic

- Surface Finish

- Molded Finish

- Connector Type

- Screw Type

- Shape

- Rectangular

- Mounting Type

- DIN Rail / Panel Mount

- Humidity %

- ≤ 90% RH

- Overheating Protection

- Yes (with suitable relay)

- Efficiency

- High

- Operating Temperature

- -5°C to +40°C

- Product Type

- Contactor

- Application

- Industrial Automation, Motor Control

- Protection Level

- IP20

- Frequency (MHz)

- 50/60 Hz

- Rated Voltage

- 660 V AC

- Energy Consumption

- Low

- Output Type

- AC

- Color

- Black & White

- Dimension (L*W*H)

- 133 x 108 x 133 mm

- Weight

- 2.8 kg

- Size

- Standard (80A)

- Phase

- Three Phase

- Input Voltage

- 220-240 V AC (Coil Voltage)

- Material

- Plastic and Metal

- No Of Poles

- 3

- Connection Type

- Screw Terminal

- Contact Material

- Silver Alloy

- Electrical Endurance

- 1 Million Operations

- Auxiliary Contacts

- 1NO + 1NC

- Shock Resistance

- 5g

- Model Number

- HMC80

- Coil Consumption

- 85 VA (at 220V AC)

- Vibration Resistance

- 2g (5~55 Hz)

- Standards Compliance

- IEC 60947-4-1

- Mechanical Endurance

- 10 Million Operations

- Rated Current

- 80A

HYUNDAI HMC80 CONTACTOR Trade Information

- Payment Terms

- Cash in Advance (CID)

- Sample Available

- Yes

- Main Domestic Market

- All India

About HYUNDAI HMC80 CONTACTOR

A contactor is an electrical device which is used for switching an electrical circuit on or off. ... These contacts are in most cases normally open and provide operating power to the load when the contactor coil is energized. Contactors are most commonly used for controlling electric motorsAdvanced Motor Control Solutions

HYUNDAI's HMC80 CONTACTOR delivers dependable performance for motor control and industrial automation. With three poles, high mechanical durability, and efficient silver alloy contacts, this device simplifies complex switching operation while ensuring long-term reliability. Its robust construction and versatile mounting options make it an ideal choice for various industrial setups.

Rugged Design for Industrial Environments

Engineered with both plastic and metal components, the HMC80 offers excellent shock (5g) and vibration resistance (2g, 5~55 Hz). Its molded finish provides superior protection, and the IP20 rating ensures safe operation in challenging conditions. The insulation material is thermoplastic, supporting efficient and safe functioning even in high-humidity settings up to 90% RH.

Efficient and Compliant Performance

Operating at a rated current of 80A and up to 660V AC, this contactor consumes minimal energy and delivers high efficiency. It is compliant with IEC 60947-4-1 standards, ensuring consistency and safety. The coil operates effectively at 220-240V AC, with low power consumption and a power factor of 0.8, making it suitable for modern automation requirements.

FAQ's of HYUNDAI HMC80 CONTACTOR:

Q: How do I install the HYUNDAI HMC80 CONTACTOR for industrial automation systems?

A: The HMC80 CONTACTOR can be mounted using either DIN rail or panel mounting options, making installation flexible. Its screw-type terminals facilitate secure electrical connections during setup in industrial automation systems.Q: What are the main benefits of using the HMC80 CONTACTOR in motor control applications?

A: Key benefits include high mechanical and electrical endurance (10 million and 1 million operations, respectively), low energy consumption, reliable auxiliary contacts, and superior shock and vibration resistance, resulting in enhanced lifespan and consistent performance.Q: When should I consider replacing the HMC80 CONTACTOR in my setup?

A: Replacement is recommended after reaching the electrical endurance limit of 1 million operations or if signs of reduced performance, overheating, or physical damage are observed during routine maintenance checks.Q: Where can the HMC80 CONTACTOR be used most effectively?

A: This contactor is best suited for motor control and industrial automation environments that demand high reliability, such as manufacturing plants, process control systems, and large-scale electrical distribution networks.Q: What process ensures protection against overheating using the HMC80 CONTACTOR?

A: Overheating protection can be achieved by pairing the HMC80 with an appropriate relay, safeguarding connected motors and circuits from thermal overload during operation.Q: How does the HMC80 CONTACTOR maintain high efficiency and safety in electrical systems?

A: Silver alloy contacts enhance conductivity and durability, while compliance with IEC 60947-4-1 and an IP20 rating provide consistent electrical performance and reliable protection in demanding industrial settings.Q: What are the usage guidelines for optimal performance and longevity of the HMC80 CONTACTOR?

A: Ensure proper installation at recommended voltage and temperature (-5C to +40C), adhere to the rated current (80A), and perform regular maintenance. Use the contactor within the specified humidity ( 90% RH) and frequency range (50/60 Hz) for best results.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hyundai Contactor Category

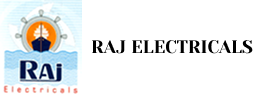

HYUNDAI HiMC 400 CONTACTOR

IP Rating : IP20

Insulation Material : Thermoplastic

Power Factor : 0.85

Dimension (L*W*H) : 270 x 180 x 260 mm

Feature : High Durability, Reliable Switching

Product Type : Contactor

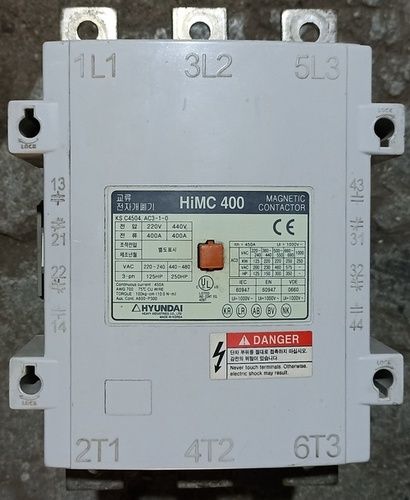

HYUNDAI HMC50 CONTACTOR

IP Rating : IP20

Insulation Material : Thermoplastic

Power Factor : 0.85

Dimension (L*W*H) : 90 mm x 91 mm x 111 mm

Feature : Long Mechanical Life, Reliable Operation

Product Type : Contactor

HYUNDAI HiMC 80 CONTACTOR

IP Rating : IP20

Insulation Material : Thermoplastic / Bakelite

Power Factor : 0.95

Dimension (L*W*H) : 110 mm x 75 mm x 114 mm

Feature : High Reliability and Long Mechanical Life

Product Type : AC Contactor

HYUNDAI HiMC 22 CONTACTOR

IP Rating : IP20

Insulation Material : Thermoplastic

Power Factor : 0.8

Dimension (L*W*H) : 66mm x 86mm x 90mm

Feature : Durable, Reliable Operation

Product Type : Contactor

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese