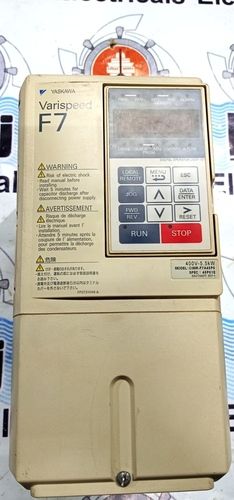

Yaskawa F7 7.5 Hp Ac Drive

Yaskawa F7 7.5 Hp Ac Drive Specification

- Feature

- Variable Speed

- Power Factor

- >0.98

- Shape

- Rectangular

- Connector Type

- Screw Type

- IP Rating

- IP20

- Efficiency

- >95%

- Mounting Type

- Panel Mount

- Surface Finish

- Matte

- Operating Temperature

- -10C to +50C

- Insulation Material

- Polycarbonate

- Overheating Protection

- YES

- Humidity %

- 95% RH (non-condensing)

- Product Type

- AC Drive

- Application

- Motor Control, Industrial Automation

- Protection Level

- Overvoltage, Undervoltage, Overcurrent, Short Circuit

- Frequency (MHz)

- 50/60 Hz

- Rated Voltage

- 380-480 V AC

- Energy Consumption

- Efficient designed for energy saving operation

- Output Type

- Analog/Digital

- Color

- Grey

- Dimension (L*W*H)

- 250 mm x 180 mm x 150 mm

- Weight

- 5.5 kg

- Phase

- Three Phase

- Input Voltage

- 380-480 V AC

- Size

- Standard

- Material

- ABS Plastic and Metal

- Connection Type

- Terminal Block

- No Of Poles

- 3

Yaskawa F7 7.5 Hp Ac Drive Trade Information

- Payment Terms

- Cash in Advance (CID)

- Sample Available

- Yes

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Yaskawa F7 7.5 Hp Ac Drive

Yaskawa F7 7.5 Hp Ac Drive

An AC drive is a device used to control the speed of an electrical motor in order to: enhance process control. reduce energy usage and generate energy efficiently. decrease mechanical stress on motor control applications.

Advanced Control Methods for Precision

Experience accurate motor control with both V/f control and vector control in the Yaskawa F7 drive. This dual control approach ensures stable operation and enables precise speed and torque adjustments, optimizing performance for a wide range of industrial applications. The high starting torque of 150% at 1 Hz further enhances its usability for demanding start-up conditions.

Reliable and Robust Design

Constructed with a durable combination of ABS plastic and metal, the Yaskawa F7 drive features an open enclosure and a matte grey finish. Forced air cooling and IP20 rating boost its longevity in tough environments, while electronic safety features-like thermal overload, overvoltage, and short circuit protection-help safeguard both equipment and operators.

Efficient Operation and Smart Connectivity

Designed for energy-saving performance, this drive boasts efficiency greater than 95% and a power factor above 0.98. Its digital LED display, RS-485 interface, and analog/digital outputs make integration and monitoring simple, while built-in features like a braking chopper and panel mounting ensure seamless operation in various systems.

FAQ's of Yaskawa F7 7.5 Hp Ac Drive:

Q: How does the Yaskawa F7 7.5 Hp AC Drive optimize motor control in industrial applications?

A: The Yaskawa F7 utilizes both V/f and vector control methods to deliver precise speed and torque regulation, making it highly effective for motor control in industrial automation. With a starting torque of 150% at 1 Hz and a maximum output frequency of 400 Hz, it supports demanding loads and complex operations.Q: What protection and safety features are integrated into the Yaskawa F7 drive?

A: The drive is equipped with electronic thermal overload protection, overvoltage, undervoltage, overcurrent, and short circuit safeguards. These features are designed to prevent equipment damage and ensure safe, uninterrupted operation even in challenging environments.Q: When should the built-in braking chopper of the F7 AC Drive be used?

A: The built-in braking chopper is beneficial during rapid motor deceleration or in applications where regenerative braking is needed. It helps dissipate excess energy safely, preventing voltage spikes and protecting the drive and connected equipment.Q: Where can the Yaskawa F7 AC Drive be installed for optimal performance?

A: This drive is suited for installation in industrial settings such as factories and automation systems. Thanks to its panel-mounting capability, compact size, and IP20 rating, it can be conveniently integrated into control panels protected from direct moisture and excessive dust.Q: What is the recommended process for connecting and configuring the Yaskawa F7 drive?

A: Connect the drive to a three-phase 380-480 V AC power supply using the screw-type terminal block. Configuration is straightforward via the digital LED display and RS-485 interface, allowing users to program control methods, output frequency, and protection parameters easily.Q: How does the F7 drive benefit energy consumption in industrial environments?

A: Engineered with energy efficiency in mind, the F7 maintains efficiency over 95% and supports variable speed operation. This reduces overall power usage and operational costs, making it a sustainable choice for continuous industrial use.Q: What makes the Yaskawa F7 suitable for use in humid or fluctuating temperature conditions?

A: The drive operates reliably in temperatures from -10C to +50C and can withstand humidity up to 95% RH (non-condensing), thanks to its robust construction, forced air cooling, and quality insulation materials. These features ensure stable performance in a wide range of industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in AC Drive Category

ABB ACS 550 75 HP AC DRIVE

Feature : Intuitive Keypad, Builtin EMC Filter, PID Control, Vector Control

Material : Plastic and Metal

Protection Level : Other, Inbuilt Protection Against Overload, Short Circuit

Dimension (L*W*H) : 200 mm x 380 mm x 567 mm

Shape : Rectangular

Output Type : Adjustable Frequency AC

Fuji Ac drive

Feature : Overload Protection, Compact Design

Material : Plastic & Metal

Protection Level : Other, IP20

Dimension (L*W*H) : 180 x 120 x 160 mm

Shape : Rectangular

Output Type : Adjustable Frequency

Toshiba VF s11 Control Card

Feature : Original, Durable, Compact Design

Material : PCB, Electronic Components

Protection Level : Other, Standard

Dimension (L*W*H) : Approx. 140mm x 70mm x 20mm

Shape : Rectangular

Output Type : Digital/Analog Signal Output

Crompton Greaves AC Drive

Feature : Variable Frequency Drive for Motor Control

Material : ABS Plastic

Protection Level : Other, Overvoltage and Overcurrent Protection

Dimension (L*W*H) : 23cm x 9cm x 5cm

Shape : Rectangular

Output Type : Variable Voltage and Frequency

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese