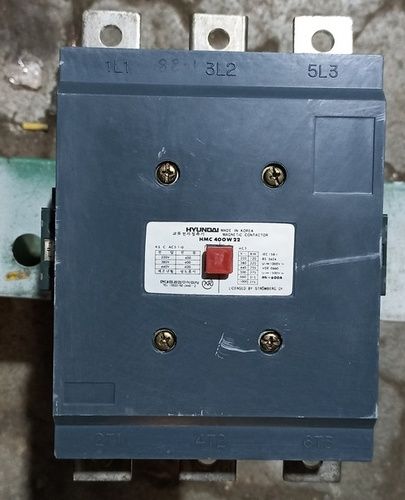

HYUNDAI HMC400 CONTACTOR

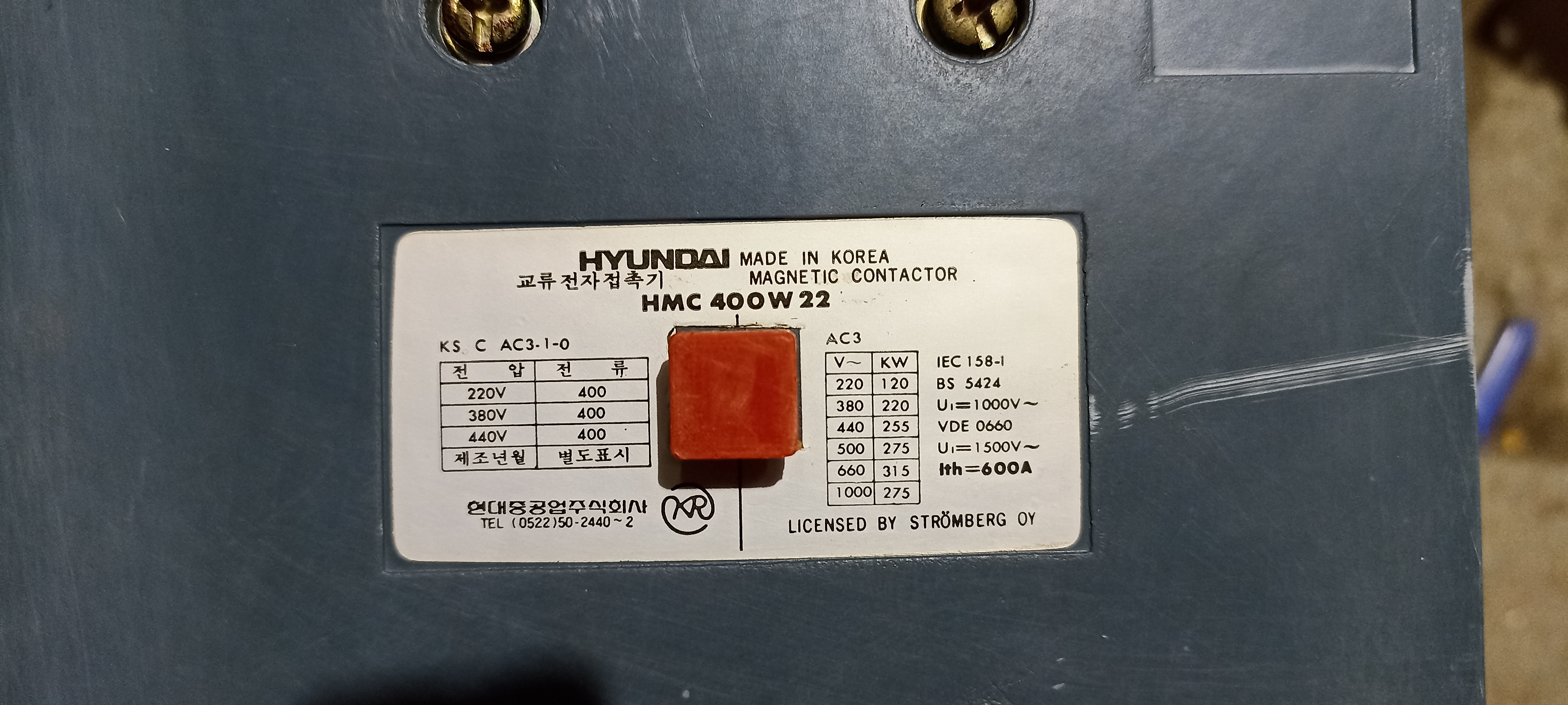

HYUNDAI HMC400 CONTACTOR Specification

- Mounting Type

- Panel Mount

- IP Rating

- IP20

- Surface Finish

- Matt

- Power Factor

- 0.85

- Feature

- High Breaking Capacity, Long Electrical Life

- Humidity %

- Up to 95% (non-condensing)

- Insulation Material

- Thermoplastic

- Efficiency

- High

- Shape

- Rectangular

- Operating Temperature

- -5 to +55°C

- Overheating Protection

- YES

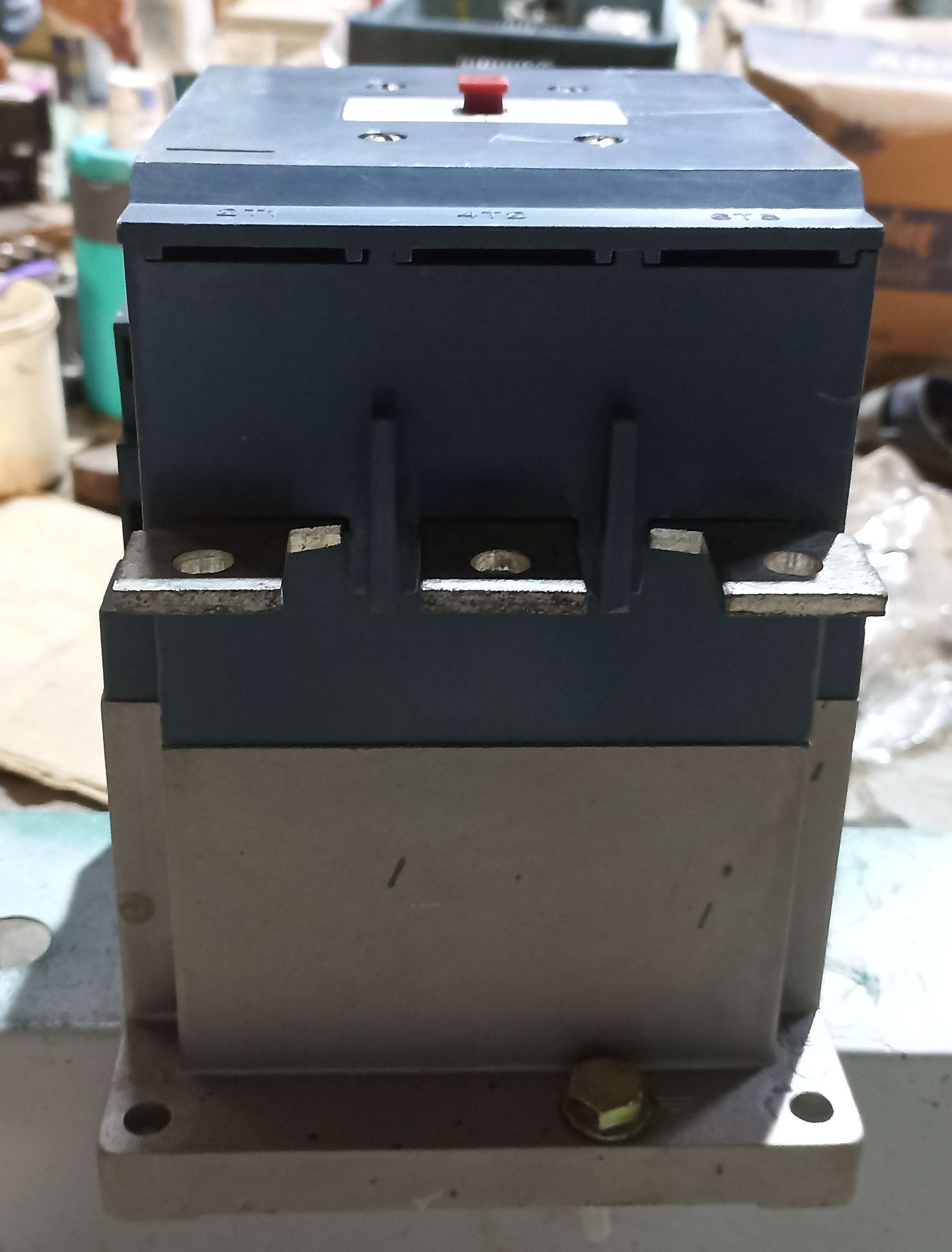

- Connector Type

- Screw Terminal

- Product Type

- Contactor

- Application

- Industrial Motor Control

- Protection Level

- IP20

- Frequency (MHz)

- 50/60 Hz

- Rated Voltage

- 690 V AC

- Energy Consumption

- Low

- Output Type

- AC

- Color

- Grey/Black

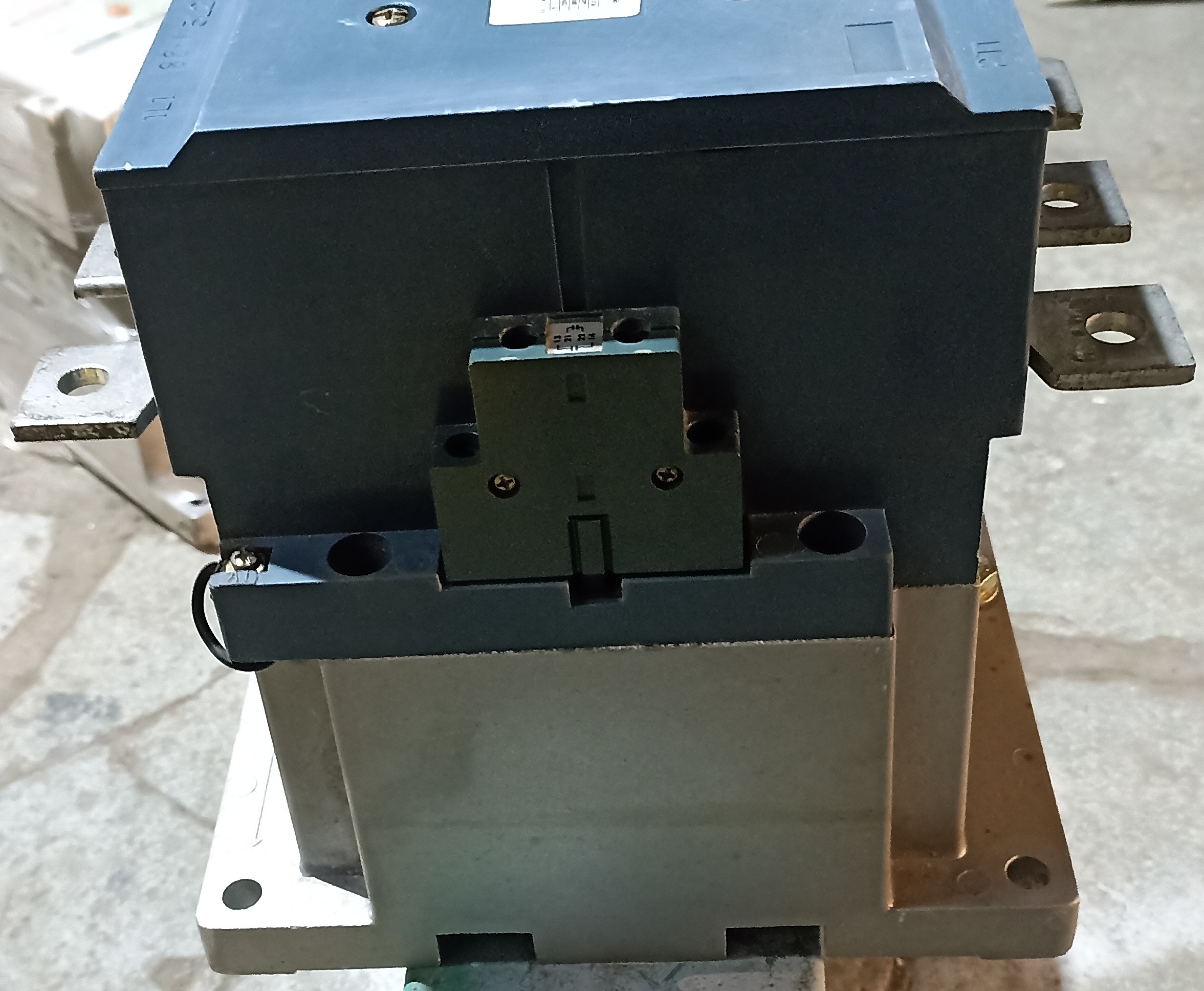

- Dimension (L*W*H)

- 360 x 191 x 198 mm

- Weight

- 18 kg

- Size

- Standard

- Phase

- Three Phase

- Input Voltage

- 220-240 V AC (Coil)

- Connection Type

- Screw Terminal

- Material

- Moulded Plastic & Metal

- No Of Poles

- 3

- Mechanical Endurance

- 5 Million Operations

- Short Circuit Withstand Capacity

- 10 kA at 415 V

- Rated Current

- 400 A

- Auxiliary Contacts

- 2NO+2NC

- Electrical Endurance

- 1 Million Operations

- Coil Voltage Range

- 110 to 415 V AC

HYUNDAI HMC400 CONTACTOR Trade Information

- Minimum Order Quantity

- 2 Number

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Sample Available

- Yes

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About HYUNDAI HMC400 CONTACTOR

We are engaged in the supply, dealing, distribution, export and import of the widest range of electrical and electronic items that would suit every type of project, economy and medium.

HMC Hyundai contactors provides convenience, economic benefit and high reliability for various industrial control systems applications, industry, households, etc.Product Specification :-

Type :- Magnetic Contactor

Make :- Hyundai

Ith :- 600A

Voltage :- 440V AC

Frequency :- 50 Hz

We Supply Our Products In All Over India And Also In Foreign Countries.

For More Details Contact : 9426838080.

Website: www.rajelectrics.com.

Email: raj_electricals@hotmail.com.

Exceptional Endurance for Demanding Applications

The HMC400 contactor boasts outstanding mechanical and electrical endurance ratings, enabling it to handle up to 5 million mechanical and 1 million electrical cycles. This ensures long-term reliability, reducing maintenance costs and downtime in demanding industrial settings where motor control is critical.

Wide Coil Voltage Range For Flexible Integration

Supporting an AC coil voltage range from 110 to 415 V, the HMC400 seamlessly integrates into a wide variety of control systems. This flexibility makes it ideal for diverse industrial installations without the need for frequent coil replacements or modifications.

High Safety Standards and Protection

With a protection level of IP20, high short circuit withstand capacity, and overheating protection features, the Hyundai HMC400 is engineered for maximum operational safety. Its thermoplastic insulation and sturdy screw terminal connections enhance both safety and performance in industrial environments.

FAQ's of HYUNDAI HMC400 CONTACTOR:

Q: How does the Hyundai HMC400 contactor improve industrial motor control processes?

A: The HMC400 provides reliable switching for heavy-duty motors, thanks to its high current capacity (400 A) and robust design. Its long mechanical and electrical endurance reduces downtime and maintenance, making it ideal for critical industrial processes requiring continuous operation.Q: What are the main benefits of using the HMC400 in industrial environments?

A: Key benefits include high breaking capacity, long operational life, energy-efficient performance, and superior protection features. The contactor's design also helps prevent overheating and supports high humidity environments, bringing durability and safety to motor control applications.Q: When should I consider selecting an HMC400 contactor for my system?

A: The HMC400 is recommended when controlling large motors or loads operating at up to 400 A and 690 V AC, especially where high switching endurance and safety are required-making it well-suited for factories, process plants, and other intensive industrial venues.Q: Where can the Hyundai HMC400 contactor be installed?

A: This contactor is panel mount compatible, suitable for mounting inside electrical panels in industrial plants or machinery. Its IP20 rating and robust enclosure allow safe installation indoors, shielding against accidental contact and dust ingress.Q: What is the process for connecting the HMC400 contactor?

A: The HMC400 uses screw terminals for secure connection of power and control wires. Standard panel mounting procedures should be followed, ensuring the unit is properly secured and all connections are tightened to the manufacturer's torque specifications for optimal performance.Q: How does the auxiliary contact configuration (2NO+2NC) enhance usage?

A: The 2NO+2NC auxiliary contacts enable flexible integration with control circuits, allowing status monitoring and advanced interlocking schemes. This improves safety and reliability by facilitating automation or remote indication in complex control systems.Q: What features ensure the longevity and efficiency of the HMC400 contactor?

A: The contactor's moulded plastic and metal structure, thermoplastic insulation, and low energy consumption coil contribute to its long lifespan. High-quality terminals, overheating protection, and efficient power factor management maximize both performance and service life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hyundai Contactor Category

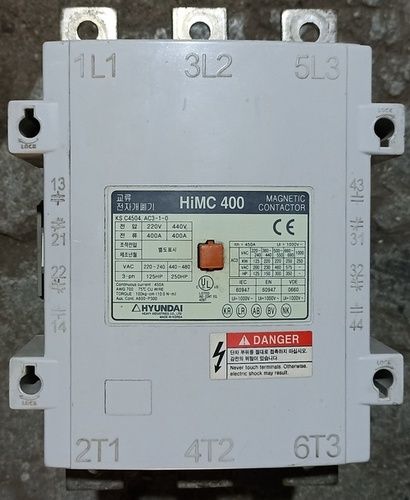

HYUNDAI HiMC 400 CONTACTOR

Minimum Order Quantity : 3

Product Type : Contactor

Insulation Material : Thermoplastic

Dimension (L*W*H) : 270 x 180 x 260 mm

Energy Consumption : Low

Phase : Three Phase

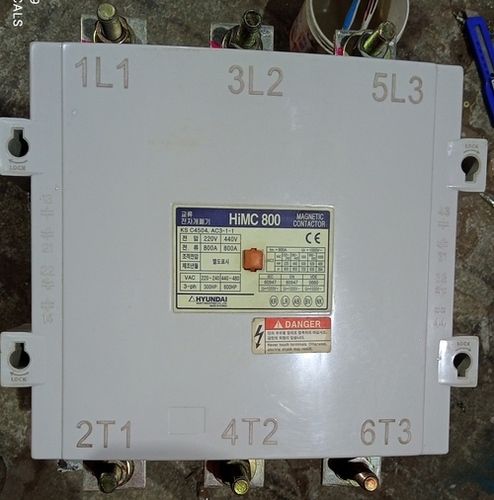

Hyundai-800 Contactor

Product Type : Power Contactor

Insulation Material : Thermoplastic

Dimension (L*W*H) : 508mm x 320mm x 477mm

Energy Consumption : Low Power Consumption

Phase : Three Phase

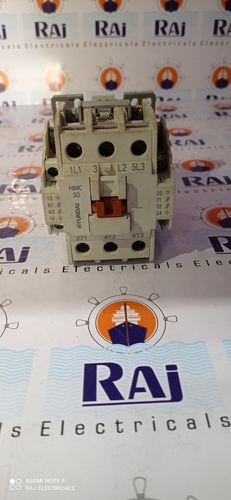

HYUNDAI HiMC 50 CONTACTOR

Product Type : Contactor

Insulation Material : Thermoplastic

Dimension (L*W*H) : 90 mm x 85 mm x 105 mm (Approx.)

Energy Consumption : Low Power Consumption

Phase : Three Phase

HYUNDAI HiMC 150 CONTACTOR

Product Type : Contactor

Insulation Material : Thermoplastic

Dimension (L*W*H) : 150mm x 110mm x 150mm

Energy Consumption : Low

Phase : Three Phase

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese