Electric AC Drive

Electric AC Drive Specification

- Surface Finish

- Powder Coated

- Efficiency

- > 95%

- Connector Type

- Screw Type

- Power Factor

- 0.98

- Feature

- Soft Start, Speed Regulation, Fault Display

- IP Rating

- IP20

- Shape

- Rectangular

- Insulation Material

- High Strength Polymer

- Mounting Type

- Panel Mount

- Product Type

- Electric AC Drive

- Application

- Industrial Automation, Motor Speed Control

- Energy Consumption

- High Efficiency, Low Energy Consumption

- Color

- Grey & Blue

- Dimension (L*W*H)

- 220 x 110 x 170 mm

- Weight

- 2.3 kg

- Phase

- Three Phase

- Size

- Standard Panel Mount Size

About Electric AC Drive

Intelligent Motor Control with High Efficiency

The electric AC drive utilizes both V/F and sensorless vector control methods, ensuring precise and dynamic motor speed regulation. Its superior energy efficiency (>95%) and effective power factor correction (0.98) promote sustainable operations while reducing operating costs. The wide speed range (1:100) makes this drive adaptable for varying industrial automation demands.

User-Friendly Design and Robust Build

Equipped with a LED digital display, the drive offers easy monitoring and configuration, while panel mounting and standard sizing ensure seamless integration into existing setups. Enhanced with a cooling fan and constructed from high strength polymer, it stands up to harsh industrial conditions. The IP20-rated powder-coated enclosure guarantees reliable operation and longevity.

FAQs of Electric AC Drive:

Q: How does the V/F and sensorless vector control benefit industrial automation?

A: V/F and sensorless vector control methods provide accurate and efficient speed regulation, enabling smooth operation and adaptable performance for various industrial applications. Sensorless vector control further enhances motor response without requiring an encoder, making it both cost-effective and reliable.Q: What is the purpose of the RS485 (Modbus) communication interface?

A: The RS485 interface with Modbus protocol allows the AC drive to connect seamlessly to industrial PLCs and automation systems. This enables remote monitoring, control, and data exchange for efficient process management and integration with smart manufacturing systems.Q: When should the soft start feature be used in motor operation?

A: The soft start feature is recommended whenever initiating the motor to minimize mechanical stress and electrical surges. This prolongs equipment lifespan and reduces maintenance costs by ensuring a gradual ramp-up in speed and current.Q: Where is the optimal mounting location for this AC drive?

A: This AC drive is designed for panel mounting within standard control cabinets or enclosures. For optimal cooling and accessibility, ensure adequate ventilation around the unit and avoid exposure to direct heat, moisture, or dust beyond IP20 protection limits.Q: What process steps are involved in setting up the drive for first-time use?

A: Begin by securely panel mounting the drive following the provided dimensions. Make electrical connections using the screw-type connectors, set up input/output phases, and connect the RS485 communication line if needed. Configure parameters via the LED display and run initial tests to verify correct operation.Q: How does the high efficiency and low energy consumption translate to user benefit?

A: The drives efficiency (>95%) and low energy consumption directly reduce operational costs and energy waste. Over long-term use, these benefits contribute to substantial savings and support eco-friendly industrial practices.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in AC Drive Category

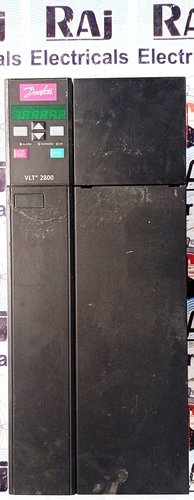

DANFOSS VLT 2800 30 HP AC DRIVE

Application : Industrial motor speed control

Product Type : AC Drive

Operating Temperature : 10C to +50C

Shape : Rectangular

Insulation Material : Epoxy coated internal PCB

IP Rating : IP20

DANFOSS VLT 6000 23 KVA AC DRIVE

Application : Industrial Automation, Motor Speed Control

Product Type : AC Drive

Operating Temperature : 10C to +50C

Shape : Rectangular

Insulation Material : High Grade Insulation Material

IP Rating : IP20

YASKAWA VARISPEED F7 60 HP AC DRIVE

Application : Industrial Motor Control

Product Type : AC Drive

Operating Temperature : 10C to +50C

Shape : Rectangular

Insulation Material : HighGrade Insulation

IP Rating : IP20

YASKAWA VARISPEED F7 75 HP AC DRIVE

Application : Pumps, Fans, Conveyors, Industrial Automation, HVAC

Product Type : AC Drive / Variable Frequency Drive (VFD)

Operating Temperature : 10C to +50C

Shape : Rectangular

Insulation Material : Class F insulation

IP Rating : IP20

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese